Washing Machine Heaters

Washing machine heating elements are electric heating elements that heat water to the temperature required for the washing process. They are usually made of stainless steel or special heat-resistant alloys. They are located inside the washing machine and heat up as the water passes through them, allowing the laundry to be cleaned.

How Do Washing Machine Resistances Work?

Washing machine heating elements are activated when water enters the machine. As the electric current passes through the resistance, the resistance heats up due to resistance and heats the water. The heated water provides the temperature required for the laundry to be cleaned and the detergent to work effectively.

What are the Technical Specifications of Washing Machine Heaters?

Heater elements in washing machines are important heating components that enable the cleaning of laundry by heating the water. Their technical specifications include:

Power (Watt): The power of washing machine heater elements is typically measured in watts. Power determines how quickly and effectively the heater can heat the water. Higher wattage values mean faster heating.

Voltage (Volt): Heater elements usually operate at the household electricity voltage of 220V or 230V. The voltage value should be compatible with the electrical system where the heater will be used.

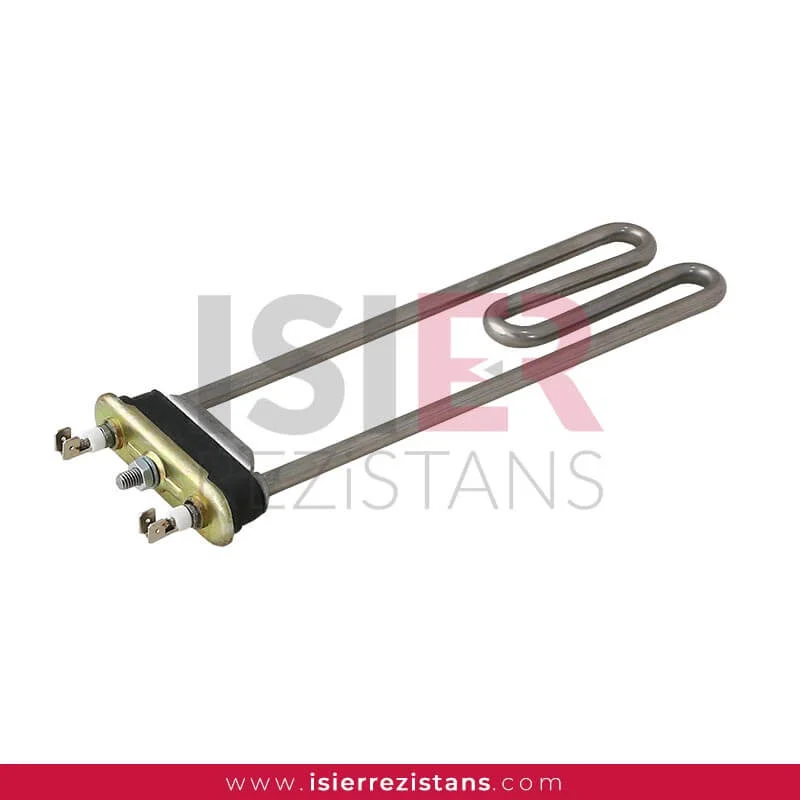

Material: Heater elements are made from stainless steel or special heat-resistant alloys to resist corrosion since they come into direct contact with water.

Size and Shape: Washing machine heater elements should be designed in standard sizes to fit specific machine models and may have a certain shape to ensure homogeneous heating of the water.

Resistance Value (Ohm): The ohm value of the heater indicates its resistance to current at a specific voltage. A well-designed washing machine heater should conform to a certain ohm value in a given application.

Heat Distribution and Dissipation: The design of the heater should be optimized to provide homogeneous heat distribution in the water, ensuring even heating of the laundry.

Thermostat and Control Systems: Some washing machine heater elements come with integrated thermostats or temperature control systems, allowing users to set and control the desired temperature level.

Ease of Installation: Heater elements should be easily integrated into a specific machine with standard mounting points and connections, providing convenience to the user.

Protection and Safety: Some heater elements may have features for preventing overheating situations to ensure safety.

These technical specifications are fundamental factors that determine the performance, energy efficiency, and user-friendly features of washing machine heater elements.

Why Choose Washing Machine Heaters?

Heater elements in washing machines are heating components that play a crucial role in cleaning laundry and offer several advantages. Here are some significant reasons why heater elements in washing machines are preferred:

Energy Efficiency: Heater elements in washing machines provide energy efficiency by directly heating the water. Rapid heating of water requires less energy consumption, thus saving energy.

Quick Heating and Fast Washing: Operating using electrical energy, heater elements in washing machines can quickly heat water to high temperatures, enabling faster cleaning of laundry.

Effective Cleaning: Heater elements in washing machines operating at high temperatures help in killing bacteria and microorganisms, ensuring hygienic cleaning of laundry.

Various Temperature Options: Heater elements in washing machines can offer various temperature options, allowing washing at suitable temperatures for different fabric types and types of stains.

Compatibility with Various Programs: Heater elements in washing machines can be designed to be compatible with different washing programs, providing users with options suitable for various washing needs.

Durability and Longevity: Heater elements in washing machines made of stainless steel or special heat-resistant alloys are known for their durability and resistance to corrosion, ensuring long-term use.

Easy Maintenance and Cleaning: Heater elements in washing machines typically require minimal maintenance and cleaning. Stainless steel surfaces are easy to clean, simplifying maintenance procedures.

Environmentally Friendly: Operating on electricity, heater elements in washing machines offer an environmentally friendly heating option as they do not use gas or other fuels. Smoke and gas emissions are lower.

Heater elements in washing machines are a preferred heating solution among users due to their advantages such as energy efficiency, quick operation, effective cleaning, and longevity.

In Which Sectors Are Washing Machine Heaters Used?

Heater elements in washing machines are commonly used heating components in household washing machines. While these heaters are typically designed for home users, they can also find application in various industrial sectors. Here are some sectors where heater elements in washing machines are used:

Household Washing Machines: The most common application is in household washing machines. These machines use heater elements to clean and wash laundry.

Hospitality Industry: Hotels, guesthouses, and other accommodation facilities may use industrial-type washing machines for their laundry needs, which can also incorporate heater elements.

Hospitals and Healthcare Facilities: Hospitals and healthcare facilities use special washing machines to clean laundry according to hygiene standards, which may include heater elements.

Laundromats: Automated laundry businesses may prefer industrial washing machines for washing laundry on a large scale, which can also utilize heater elements.

Educational Institutions and Cafeterias: Schools, universities, and other educational institutions may have substantial laundry washing needs. Devices in cafeterias and student accommodation units may also incorporate heater elements.

The use of heater elements in washing machines in these sectors aims to meet hygiene standards, provide efficient cleaning, and offer general ease of use. Particularly in industrial-type washing machines, effective results can be achieved by using these heater elements for large-volume laundry washing processes.

What Do Washing Machine Heaters Do?

Heater elements in washing machines are electric heating components that provide various advantages by heating water during the laundry cleaning process. Here are the key functions of heater elements in washing machines:

Cleaning by Heating Water: Among their primary functions is cleaning laundry by heating water. This allows high temperatures to effectively clean stains, bacteria, and microorganisms from the laundry.

Energy Efficiency: Since they operate using electrical energy, heater elements in washing machines provide energy efficiency by directly heating water, optimizing energy consumption for an economical solution.

Quick Washing Capability: Heater elements in washing machines, powered by electricity, can rapidly heat water to achieve high temperatures, facilitating faster cleaning of laundry.

Hygienic Cleaning: Operating at high temperatures, heater elements in washing machines aid in killing bacteria and microorganisms, ensuring hygienic cleaning of the laundry.

Various Temperature Options: They offer users various temperature options to meet different washing needs, providing suitable washing conditions for different fabric types and stains.

Low Maintenance Requirement: Heater elements in washing machines typically require low maintenance due to their durable construction from stainless steel or special alloys, offering long-term usage.

Environmentally Friendly Solution: Operating on electricity and not consuming fuel, heater elements in washing machines provide an environmentally friendly heating solution with lower smoke and gas emissions.

Heater elements in washing machines offer users a practical laundry washing solution by enhancing cleaning performance, providing energy savings, and meeting hygiene standards.