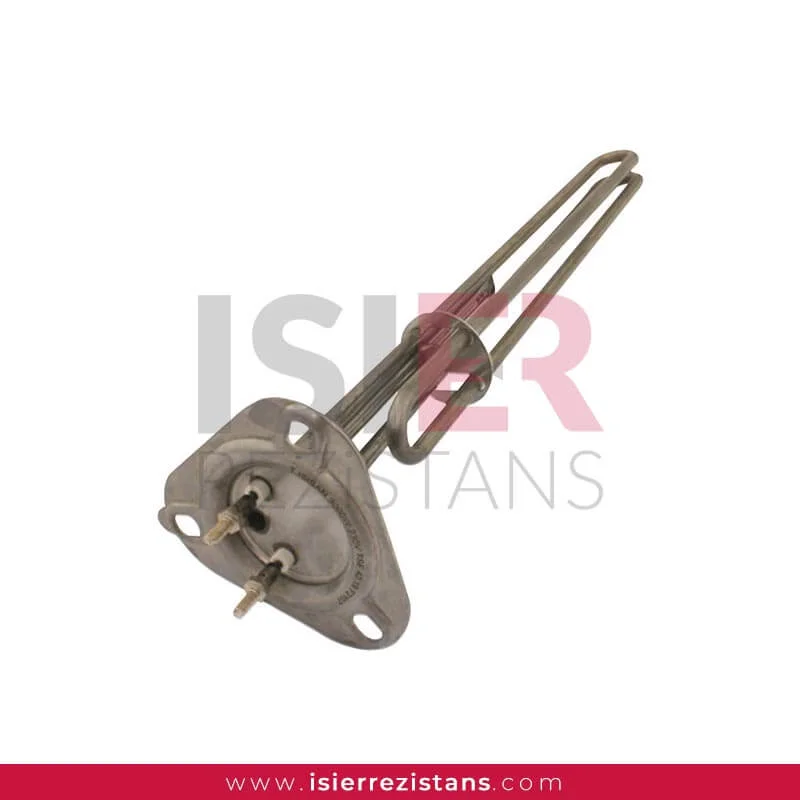

Triangle Heaters

Triangular heating elements are heating elements with a special geometric shape. They get their name from their triangular shape. They are commonly used in industrial furnaces, boilers, temperature control systems and process heating applications. The unique geometry of triangular resistors is designed to provide a more effective and efficient heat transfer in specific applications.

How Triangle Heaters Work

The working principle of triangle heaters is based on generating heat by passing an electric current through the heater. The electric current encounters resistance within the heater, resulting in the generation of heat. The triangular shape of the heaters provides a larger surface area, allowing for more effective heat transfer.

Triangle heaters play a significant role in industrial heating systems due to their special geometric structures and superior heat transfer properties. This particular type of heater, available through the Isıer Heater website, is preferred in many sectors for its durability and efficiency. Triangle heaters can be designed to meet the requirements of each application, offering reliable heating solutions in various industrial and commercial fields.

What are the Technical Specifications of Triangle Heaters ?

Triangle heaters are a special type of heating element used in industrial heating applications. The technical specifications of these heaters are important factors that determine their performance, durability, and application areas. Here are the basic technical specifications of triangle heaters:

Power (Watt): The power of triangle heaters is typically measured in watts. This determines how much heat the heater can generate and the amount of heat it can provide in a specific application. The wattage value expresses the heater’s capacity to convert electrical energy into heat.

Voltage (Volt): Voltage should be compatible with the electrical system the heater operates on. Triangle heaters typically operate at standard household electricity voltages of 220V or 230V. However, models produced for special applications may be available at different voltages.

Material: Triangle heaters are usually made of heat-resistant materials such as stainless steel or nickel-chromium alloys. These materials provide resistance to high temperatures and corrosion resistance.

Size and Geometry: Size and geometric structure are important because triangle heaters have special triangular shapes. This allows the heater to be effectively positioned within a specific application or device.

Resistance Value (Ohm): The ohm value of the heater indicates its resistance to current at a specific voltage. A well-designed triangle heater should match the ohm value for a particular application.

Ease of Installation: Heater installation should be designed to facilitate integration into the user’s device or system. Standard mounting points and connections provide convenience to the user.

Heat Control: Some triangle heaters may include integrated temperature control systems or thermostats. This ensures that the heater is maintained at a specific temperature, optimizing heat control in the application.

Durability and Waterproofing: Triangle heaters should be waterproof as they often come into contact with water. Special coatings or stainless steel materials can enhance durability.

Application Areas and Compatibility: Triangle heaters can be designed to suit specific industrial applications. Heaters with suitable size, power, and technical specifications provide the best results for a particular application.

These technical specifications are crucial for triangle heaters to effectively operate in a specific application or industrial process. Choosing the right triangle heater is of great importance to ensure desired performance and durability.

What are the Uses of Triangle Heaters?

Triangle heaters are a specialized type of heating element with a wide range of applications in industrial heating processes. Here are some areas where triangle heaters are commonly used:

Industrial Ovens: Triangle heaters are frequently employed in industrial ovens supporting high-temperature processes used in metalworking, ceramic production, glass industry, and other industrial applications.

Metalworking and Foundries: Triangle heaters are used for shaping, melting, or hot processes of metal. Precise heat control and uniform heat distribution are crucial in these applications.

Chemical and Petrochemical Industry: Triangle heaters are commonly used in process heating systems for controlling chemical reactions and in the petrochemical industry.

Food Industry: Triangle heaters are utilized in food industry applications such as industrial ovens, drying systems, and cooking appliances, enabling processing of food products at desired temperatures.

Plastic and Rubber Industry: Triangle heaters are preferred for heating and shaping processes in plastic and rubber production. Maintaining products at specific temperatures or melting may be required in these industries.

Automotive Industry: In the automotive sector, triangle heaters can be used in paint ovens, drying systems, and other heating applications.

Textile Industry: Triangle heaters can be used in fabric drying and shaping processes in the textile industry. Their ability to control heat precisely can enhance the quality of textile products.

Paper and Pulp Industry: In the paper and cellulose industry, triangle heaters can be used for temperature control in paper production and processing stages.

Electronic Industry: In electronic manufacturing processes, triangle heaters are used to meet the heating needs of circuit board production, soldering, and other precision heating requirements.

Power Plants: In power generation facilities, triangle heaters can be used, especially in steam production and heating systems.

These applications reflect the ability of triangle heaters to be effectively utilized across a wide spectrum of industries. Designed to provide reliable performance at high temperatures, these heaters can be adapted to various industrial applications.

Why Triangular Heaters should be preferred?

Triangle heaters stand out in a variety of industrial heating applications for several reasons. Here are some key factors contributing to why triangle heaters are preferred:

Homogeneous Heat Distribution: Triangle heaters provide homogeneous heat distribution thanks to their unique geometric structure. This feature ensures that every point of the heated material receives heat evenly, thus maintaining the desired temperature.

High Efficiency: Due to their unique shapes, triangle heaters have a larger surface area, enabling more effective heat transfer and consequently high efficiency.

Versatile Application Areas: Triangle heaters can be designed in various sizes and power levels suitable for a wide range of industrial applications. This allows them to be used in different sectors and applications.

Durability: Made from durable materials such as stainless steel or nickel-chromium alloys, triangle heaters are long-lasting and can withstand harsh industrial conditions.

Flexibility: Triangle heaters can be customized to fit various industrial applications. Size, power, and other technical specifications can be adapted to specific needs.

Precise Temperature Control: Some triangle heaters may come equipped with integrated temperature control systems or thermostats, allowing for precise temperature regulation.

Usage Across Various Industries: Triangle heaters can be used in metalworking, chemical, food, automotive, textile, and many other industrial sectors. Their broad application areas make them a versatile and widespread choice.

High Temperature Resistance: Triangle heaters, designed with durable materials, maintain their durability when exposed to high temperatures in industrial heating processes.

Rapid Heating Capability: Thanks to their special designs and materials, triangle heaters possess the ability to heat up quickly. This can accelerate processes and enhance energy efficiency.

Compatible Design: Triangle heaters typically feature a compatible design that allows for easy integration into industrial devices or systems.

These reasons are significant factors that make triangle heaters preferred in industrial heating applications. They have the capacity to provide reliable and effective heating solutions across various sectors.

Coffee Heaters

Coffee heating elements are heating elements used in coffee machines. They ensure a quality brew by keeping the water at the ideal temperature to extract the essence of the coffee beans. Coffee heating elements are usually designed to heat water quickly, be energy efficient and long lasting.

Working Principle of Coffee Heaters:

Electric Current Coffee resistors work by supplying electric current to the coffee machine. The electric current is passed through the resistance and the resistance heats up.

Water Heating: The heat from the heating element heats the water, providing the necessary temperature for the brewing process. The heating element in the coffee machine brings the water to a certain temperature, which creates a suitable environment to extract the aroma of the coffee beans.

Temperature Control: Good quality coffee percolators may include integrated temperature control systems or thermostats. This feature ensures that the water is kept at the desired temperature, making it easier to brew a delicious cup of coffee.

What are the Technical Specifications of Coffee Heaters?

The technical specifications of coffee heaters are crucial factors that determine their performance, durability, and ease of use. Here are some key technical specifications of coffee heaters:

Power (Watt): The power of coffee heaters is typically measured in watts. This determines how much the heater can heat up and how quickly it can heat the water. Coffee machine heaters usually have powers ranging from 800W to 1500W.

Voltage: Coffee heaters typically operate at the standard household electricity voltage of 220V or 230V. However, models compatible with different voltages for industrial use or different electrical systems may also be available.

Material: Coffee heaters are often made of heat-resistant materials such as stainless steel or nickel-chromium alloys. Stainless steel is preferred for its durability, corrosion resistance, and hygienic properties.

Size and Shape: Coffee heaters can come in different sizes and shapes depending on the design and intended use of the coffee machine. Standard-sized heaters are usually designed to fit common coffee machines.

Ease of Installation: Heater installation should be designed to easily integrate into users’ coffee machines. Standard connection points and installation instructions provide convenience to users.

Heat Control: Some coffee heaters may be equipped with integrated temperature sensors or thermostats. This feature ensures that the water is maintained at a specific temperature, optimizing the brewing process.

Rapid Heating Feature: High-quality coffee heaters heat water quickly, speeding up the brewing process. This feature provides users with a fast and effective coffee experience.

Safety Features: Some coffee heaters may have safety features to prevent overheating and ensure safe use. Features like automatic shut-off or overheat protection enhance user safety.

Durability and Waterproofing: Coffee heaters should be waterproof as they come into contact with water. Using stainless steel or special coatings can enhance durability.

Compatible Brands and Models: Some coffee heaters may be designed to be compatible with specific brands and models of coffee machines. This ensures users select the right heater for their machine.

These technical specifications are key determinants of the performance and usability of coffee heaters. When choosing a heater for their coffee machine, users should pay attention to these specifications.

What are the Uses of Coffee Heaters?

Coffee heaters are heating elements commonly used in coffee machines. These heaters maintain water at the appropriate temperature to extract flavor from coffee beans, ensuring a quality brewing process. Coffee heaters are preferred in various usage areas:

Home Kitchens: Coffee machines used in homes typically contain coffee heaters. In home kitchens, coffee heaters offer users the ability to brew coffee quickly, conveniently, and with great taste.

Cafes and Coffee Shops: Commercial coffee machines used in cafes and coffee shops feature coffee heaters extensively. These machines are designed to withstand heavy usage and aim to provide customers with quality coffee quickly due to their rapid heating capabilities.

Restaurants and Hotel Kitchens: In restaurants and hotel kitchens, coffee heaters are used in special coffee machines to serve guests fresh and delicious coffee.

Offices and Workplaces: Coffee machines found in offices and workplaces use coffee heaters to provide employees with an energizing break.

Fast Service Points: Fast-food restaurants utilize coffee heaters to prepare coffee quickly and efficiently. As quick service is important in such establishments, coffee heaters with instant heating capabilities meet this need.

Airports and Train Stations: Coffee heaters are commonly used in transportation hubs such as airports and train stations to provide passengers with a quick energy boost.

Educational Institutions: School cafeterias, university cafeterias, and other educational institutions use coffee heaters to serve coffee to students and staff.

Meeting and Conference Rooms: Coffee heaters may be used in meeting and conference rooms to offer coffee service to participants during business meetings and conferences.

Coffee heaters, with their wide range of applications, are essential components preferred in various industries to optimize the coffee brewing process and provide quality coffee.