Sectoral Heaters

Our Heater solutions, one of the most reliable and innovative products we offer, provide unparalleled performance for your industrial needs. Designed and manufactured by our expert team, focusing on high-quality standards and customer satisfaction, our products ensure top-notch quality and efficiency.

Sectoral Heaters Types

Your Solution Partner for All Your Heater Needs

Most Used/Preferred Heaters by Sectors?

Various types of heaters are preferred according to the needs of different industries, but there are some popular heater types:

Industrial Heating:

Tube Heaters: Used for heating liquids and gases.

Band Heaters: Used for heating cylindrical or flat surfaces.

Cartridge Heaters: Designed for use in tight spaces or holes.

Coil Heaters: Used for heating air or gas fluids.

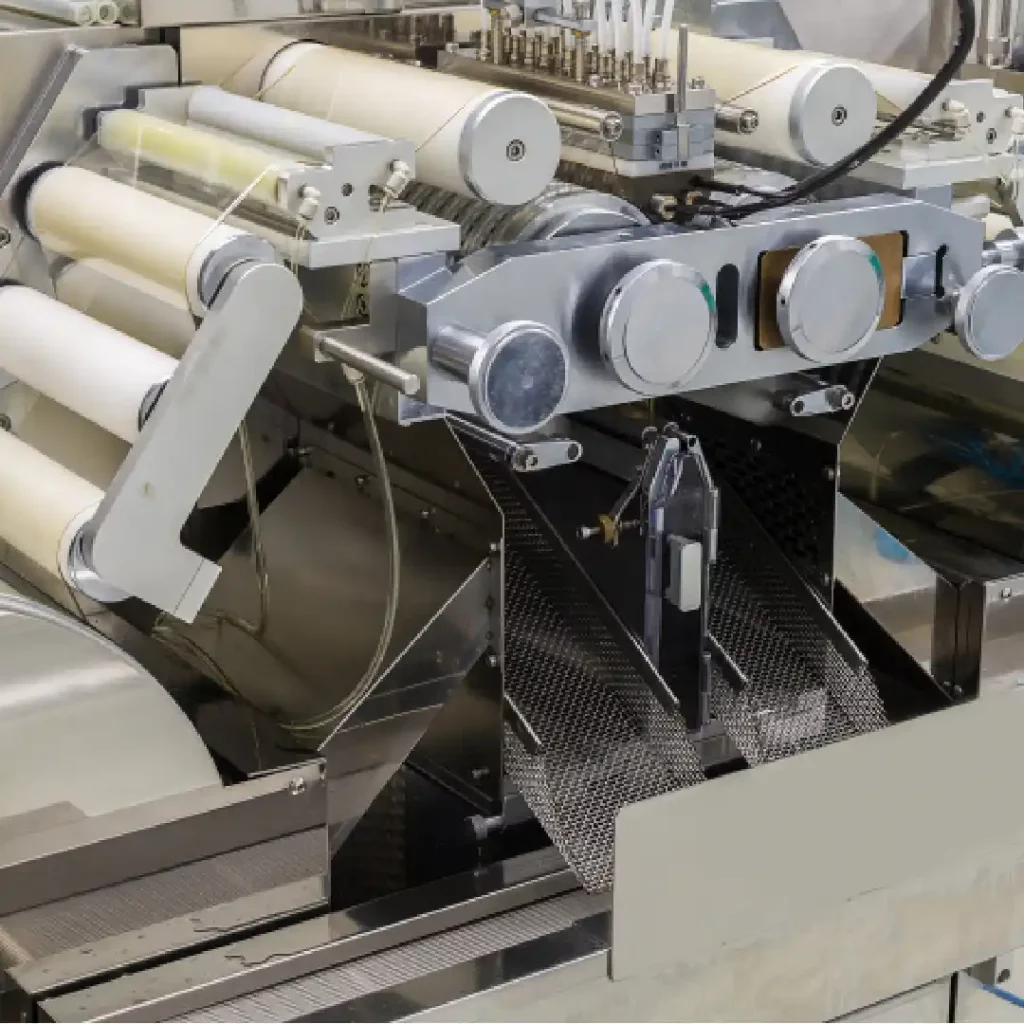

Plastic and Polymer Industry:

Infrared Heaters: Commonly used in plastic extrusion and injection processes.

Band Heaters: Designed for use in plastic molding machines.

Food and Beverage Industry:

Tube Heaters: Used in boilers, cooking equipment, and temperature control systems.

Plate Heaters: Widely used in ovens, grills, and frying equipment.

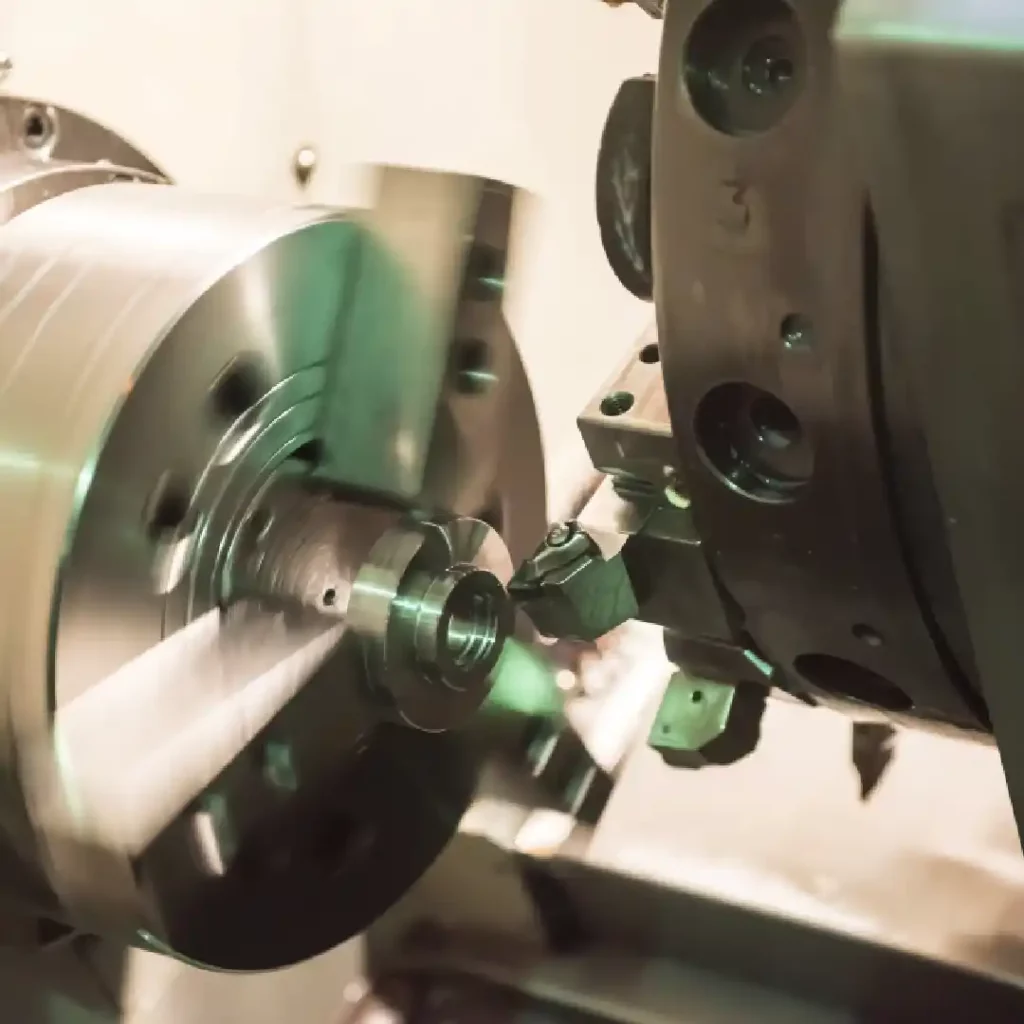

Automotive Industry:

Coil Heaters: Used for vehicle interior heating systems, seat heating, and cabin heating.

Hose Heaters: Used in vehicle engine cooling systems.

Metal Processing Industry:

Industrial Furnace Heaters: Used in metal melting, casting, and heat treatment applications.

Wire Heaters: Used for heating metal pipes and pipelines.

Chemical Industry:

Plate Heaters: Used in heating systems where chemical reactions are controlled.

Coil Heaters: Used for heating tanks and reactors used in chemical processes.

These are examples of some heater types commonly used across industries. However, since there are specific requirements and applications in each sector, heater selection should always be carefully done to meet specific needs.

Importance of Heaters in Manufacturing and Production Sector

Heaters hold significant importance in the manufacturing and production sector as they are utilized to meet heating and control requirements in numerous industrial processes. Here are some key points highlighting the importance of heaters in the manufacturing and production sector:

Heating and Control in Production Processes: Heaters are employed in many production processes such as metal processing, plastic injection, food processing, chemical manufacturing, and similar processes. They are used for heating, melting, shaping materials, or accelerating reactions.

Energy Efficiency: Heaters can be optimized to ensure energy efficiency. A facility equipped with a properly designed and controlled heater system can reduce energy costs and facilitate more sustainable production.

Product Quality and Efficiency: Proper temperature control significantly impacts product quality and efficiency. Heaters enhance product quality and increase production efficiency by providing stable temperatures during manufacturing processes.

Customizability and Flexibility: Heaters can be customized to meet diverse requirements and manufactured in various shapes, sizes, and specifications. This capability allows for providing solutions tailored to different industrial applications and flexibility in production processes.

Cost-effectiveness: Heaters are generally more cost-effective compared to other heating methods. They offer a competitive option in terms of both initial investment costs and operational expenses.

For these reasons, heaters are considered a fundamental component in the manufacturing and production sector, contributing to the efficient and reliable operation of many industrial businesses.

Why Production and Manufacturing Industries Should Use Heaters

Heaters are an essential component that needs to be used in many industries. Here are some key reasons why these sectors need to use heaters:

Process Control and Quality: Heaters help optimize production processes by providing temperature control. Materials held at the correct temperature allow for more consistent and higher quality products.

Energy Efficiency: Well-designed and efficient heater systems can reduce energy costs. Energy efficiency reduces operating costs, providing a competitive advantage, and also reduces environmental impact.

Productivity and Efficiency: Heaters can increase productivity by enabling processes to be carried out faster and more efficiently. Rapid heating of materials or acceleration of reactions enhances production efficiency.

Flexibility and Adaptability: Heaters can be customized to suit various applications. This allows for providing solutions tailored to the needs of different sectors and adapting to changing requirements.

Safety: Modern heater systems are designed in accordance with safety standards and can be used safely. Proper monitoring and control help prevent hazardous situations.

Cost-effectiveness: Heaters are often more cost-effective compared to other heating methods. They offer an economical option in terms of both initial investment and operating costs.

For these reasons, using heaters in many industries is important. It offers advantages in terms of efficiency, quality, safety, and cost, helping businesses to remain competitive.