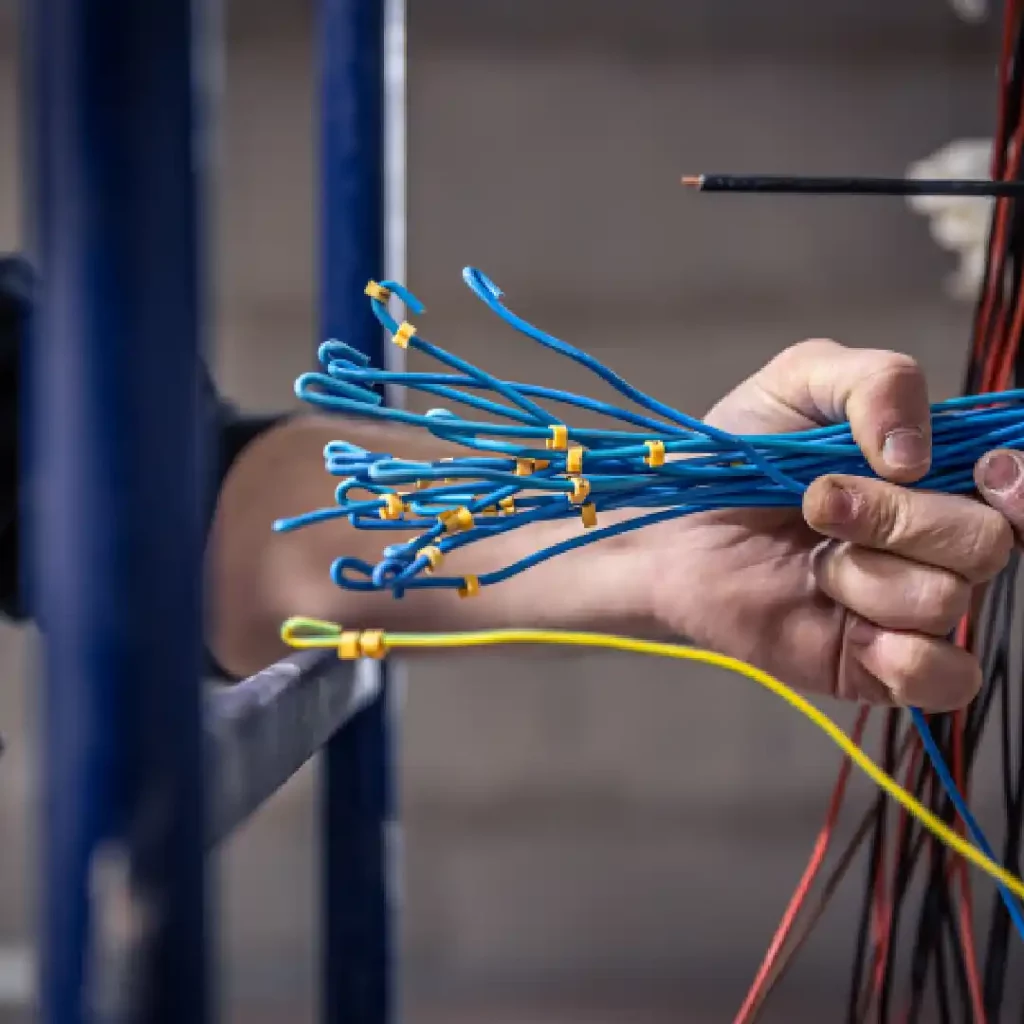

Cable Manufacturing Heaters

Heat Control: Heaters are used to control and maintain the temperature inside the cable at the desired level. Especially in industrial applications, cables may need to operate within specific temperature ranges. Heaters ensure this temperature control, thereby enhancing the performance of the cable material.

Prevention of Freezing: Heaters are used to prevent cables from freezing in cold weather conditions. This is particularly important for cables used outdoors or in cold storage areas.

Temperature Balancing: In some applications, heaters are used to balance temperature differences inside the cable. This is important for maintaining the properties of the cable material and ensuring long-term performance.

Chemical Resistance: Heaters can be used to protect cable materials against chemical substances. By providing chemical resistance, heaters can extend the service life of cables in industrial environments.

Anti-Corrosion Properties: Cable heaters can provide resistance to corrosion, which is particularly important for cables exposed to aggressive environmental conditions.

Heaters used in cable manufacturing may often have special designs and can be manufactured to meet specific application requirements. Therefore, different types of heaters may be preferred depending on the type of cable to be used and the application.

Our Products

Your Solution Partner for All Your Resistance Needs

The Importance of Cable Manufacturing Heaters

Reliability and Performance: Heaters used in cable manufacturing ensure reliable operation of cables and achieve desired performance levels. Particularly in industrial applications, cables may need to operate within specific temperature ranges or withstand various environmental conditions. Heaters can help cable materials function properly under these requirements.

Temperature Control: Heaters are utilized to control the temperature inside the cable. This prevents cable materials from overheating or cooling excessively, thereby prolonging the lifespan of the cable system and ensuring safer operation.

Cost and Efficiency: The use of appropriate heaters can optimize energy consumption and reduce costs. Additionally, enhancing the temperature and environmental resistance of cable materials can decrease maintenance expenses and increase system efficiency.

Adaptability for Special Applications: Heaters used in cable manufacturing can be specially designed to adapt to various industrial and commercial applications. For instance, they can be tailored to meet different requirements such as anti-corrosion properties, chemical resistance, or protection against freezing.

Durability and Longevity: Heaters employed in cable manufacturing enhance the durability of cables, ensuring long-lasting performance. This is particularly important for cables used in industrial environments and challenging conditions.

In conclusion, the correct selection and use of heaters in cable manufacturing ensure cables operate reliably, durably, and with high performance.

Technical Specifications of Heating Used in Cable Manufacturing Industry

The technical specifications of heaters used in the cable manufacturing sector can vary depending on the application and requirements they will be used for. However, generally, some basic technical specifications may include:

Nominal Power (Watt): The nominal power of the heater indicates its ability to operate at a specific temperature under a certain electrical current. This feature is important for evaluating whether the heater is suitable for a specific application.

Nominal Voltage (Volt): The nominal voltage of the heater specifies the electrical voltage required for it to operate safely and effectively for a particular application.

Resistance Value (Ohm): The resistance value of the heater represents its resistance to electrical current at a specific temperature. This value is important for determining the suitability of the heater for application requirements.

Temperature Coefficient: The temperature coefficient of the heater indicates how sensitive the resistance value is to changes in temperature. This is particularly important for applications requiring temperature control.

Insulation Material: The insulation material covering the heater affects its resistance to environmental conditions, chemicals, and other external factors. Different insulation materials may be preferred for different applications.

Dimensions and Design: The dimensions and design of the heater are determined to ensure compatibility with the cable or connection system it will be used with. This is important for ease of installation and mechanical durability.

Operating Temperature Range: The operating temperature range of the heater specifies its capacity to operate safely and effectively within a certain temperature range. This feature is important for applications requiring temperature control in cable manufacturing.

Protection Class and Standards: Heaters generally need to comply with specific protection classes (IP ratings) and industry standards. This indicates their resistance to various environmental conditions depending on the application area.

These technical specifications should be considered for the proper selection and ensuring adequate performance of heaters used in cable manufacturing. Relevant industry standards and application requirements can provide guidance on heater selection.

Cartridge Heating Used in Cable Manufacturing Sector

Cartridge heaters used in the cable manufacturing sector are particularly employed to control the temperature inside the cable, prevent freezing, or maintain specific temperature conditions, especially in industrial applications. These heaters generate heat using the electrical resistance within the cable and keep the cable materials within the desired temperature range.

Material: Cartridge heaters are typically made of high-resistance materials such as nickel-chromium alloys or iron-chromium-aluminum alloys. These materials can withstand high temperatures and possess suitable properties to achieve the desired resistance values.

Resistance Value: The resistance value of cartridge heaters is selected to ensure the required temperature control for a specific application. The resistance value indicates the electrical resistance of the heater.

Power Capacity: The power capacity of cartridge heaters determines their ability to operate within a specific temperature range. This expresses the capacity of the heater to operate at a certain power level and voltage.

Dimensions and Design: The dimensions and design of cartridge heaters are determined to accommodate the cable diameter and application requirements. This is important for ease of installation and mechanical durability.

Temperature Control Elements: Some cartridge heater designs may include temperature control elements. These elements measure the temperature inside the cable and adjust the operating parameters of the heater accordingly.

Protection Class and Standards: Cartridge heaters generally need to comply with specific protection classes (IP ratings) and industry standards. This indicates their resistance to various environmental conditions depending on the application area.

Cartridge heaters can be used in various applications for temperature control and protection within cables. These heaters play a significant role in increasing the reliability of cable systems, especially in cold weather conditions, areas exposed to chemical substances, or industrial facilities.