Thermosyphon Heaters

Thermosyphon heating elements are specially designed electric heating elements that provide hot water by directly heating water. They utilize a natural circulation system that heats cold water in a tank, from which hot water rises. This increases energy efficiency and makes the water heating process more efficient.

How Do Thermosyphon Heaters Work?

Solar Collector: Thermosyphon heating elements are usually integrated with a solar collector. The solar collector absorbs sunlight and transfers the heat to the water.

In-Tank Resistor: The thermosyphon heating element in the tank heats the water directly to produce hot water. This heating element heats the water rapidly using electrical energy.

Natural Circulation: The heated water rises due to its reduced density and is displaced by the cold water inlet. This natural circulation process makes the hot water available.

Hot Water Storage: The heated water is stored in a storage tank and can be used when needed. This ensures a continuous supply of hot water.

What are the Technical Specifications of the Thermosyphon Heater?

Heater elements are special designed heating elements that enable the production of hot water by heating the water. The technical specifications of these heaters may vary depending on their intended use, power capacities, and integration methods. However, generally, the technical specifications of heater elements are based on the following factors:

Power Capacity: The power capacities of heater elements are typically measured in watts. This indicates how much water the heater can heat in a certain period of time. For example, a heater element with a power capacity of 2000 watts can heat water more quickly.

Voltage Value: The electrical voltage required for the operation of the heater element is usually expressed in volts (V). For instance, it may be stated that a heater element operates with a voltage of 230V.

Material and Coating: Heater elements are typically made of stainless steel, copper, or other durable materials. The choice of material is important for durability and heat conduction. Additionally, using special coatings can reduce limescale buildup.

Size and Geometry: The dimensions and geometry of the heater element may vary depending on the design of the water heater system it will be used in. These factors ensure proper integration of the heater element into the water heater system.

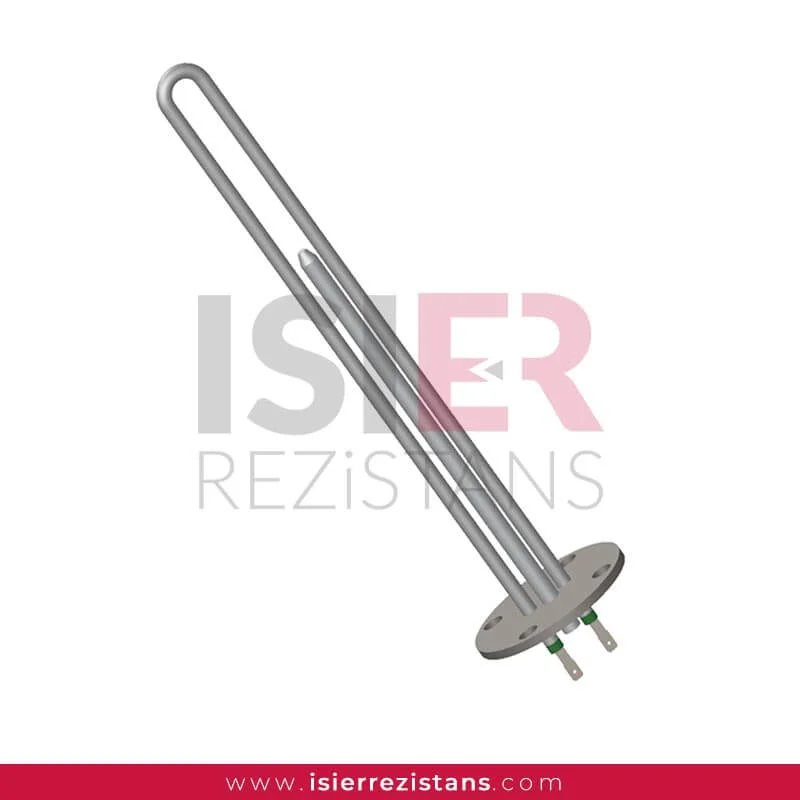

Connection Type: How the heater element connects to the water heater system is also important. Some heater elements have threaded connections, while others have flange connections. This affects the installation and replacement processes of the heater element.

Protective Features: Some heater element models may have protective features against overheating, dry heating, or excessive current, for example. These features ensure the safe and long-lasting operation of the heater element.

Operating Temperature: The maximum operating temperature of the heater element is specified. This is a factor that affects the durability of the heater element and ensures reaching the maximum temperature of the water.

Integration Capability: Heater elements should generally be capable of being integrated with solar energy collectors or other heating systems. Integration capability can enhance the efficiency of the water heater system.

Warranty Period: Manufacturers typically provide a certain warranty period for their products. The warranty period guarantees trouble-free operation of the product for a specific period of time.

These technical specifications play a significant role in determining the performance, durability, and suitability of heater elements. Depending on the environment and application they will be used in, different heater element models may be preferred.

What Do Thermosyphon Heaters Do?

Heater elements are special design heating elements used to meet the demand for hot water. These heaters are particularly used in various applications, especially when integrated with solar energy, to provide energy efficiency. Here are the main functions of heater elements:

Hot Water Production: Heater elements directly heat water to produce hot water. This hot water can be used for domestic purposes, temperature control in industrial facilities, hotels, hospitals, and many other applications.

Energy Saving: Heater elements integrated with solar energy utilize solar power to heat water, thus providing energy savings and reducing dependency on traditional energy sources.

Natural Circulation: Heater elements operate on the principle of natural circulation, causing heated water to rise and cold water to take its place, triggering a continuous and automatic water heating process.

Sustainable Energy Use: Heater elements powered by solar energy utilize a sustainable and eco-friendly energy source for water heating.

Easy Installation: Heater elements typically require simple installation and can be easily integrated, providing ease of use.

Various Application Areas: Heater elements can be used to meet various hot water needs in homes, hotels, hospitals, industrial facilities, and many other application areas.

Local Energy Production: Heater elements encourage local energy production by utilizing solar energy, which can increase energy independence and reduce dependence on external energy sources.

Low Operating Costs: When integrated with solar energy, heater elements offer low operating costs since solar energy is a free energy source.

Heater elements provide a reliable, energy-efficient, and environmentally friendly solution for meeting hot water needs. With these features, they play an important role in modern heating systems and energy-saving applications.

What are the Uses of Thermosyphon Heaters?

Heater elements are an effective and energy-efficient heating solution used to meet the demand for hot water in various application areas. Here are the usage areas of heater elements:

Homes and Residences: Heater elements are used in homes to meet the demand for hot water. They are commonly preferred to meet hot water needs in bathrooms, kitchens, and general use areas.

Hotels and Accommodation Facilities: Heater elements are used in hotels to meet the hot water needs of guests. Hot water is an important factor for providing a comfortable stay experience in hotels.

Hospitals and Healthcare Facilities: Due to hygiene and sterilization requirements in healthcare facilities, there is a high demand for hot water. Heater elements are used in hospitals for sterilization, bathing, and other medical applications.

Industrial Facilities: In factories, production facilities, and industrial areas, heater elements are used for temperature control in processes, cleaning operations, and other industrial applications.

Restaurants and Food Service: Hot water is important for kitchen activities and cleaning operations in restaurants and food service establishments. Heater elements provide hot water supply in such establishments.

Educational Institutions and Public Buildings: Heater elements are used in buildings with mass usage areas such as schools, universities, and public buildings to meet the hot water demand in general use areas.

Sports and Recreation Facilities: Hot water is used for heating shower areas and swimming pools in sports gyms, swimming pools, and other recreation facilities. Heater elements provide hot water supply in such facilities.

Agriculture and Animal Husbandry: Heater elements are used in agricultural facilities and animal farms for heating irrigation water, animal shelters, and other agricultural applications.

Power Plants: When integrated with solar energy collectors, heater elements enable electricity generation using solar energy.

Maritime and Shipbuilding Industry: In the maritime sector, heater elements are used in ships and marine vessels to meet the hot water demand and heat water systems inside the ship.

These application areas demonstrate the wide range of uses of heater elements and their significant role in various sectors.