Teapot Heaters

Tea has an important place in Turkish culture and is an indispensable drink in the daily lives of many people. One of the key elements of the teapots used to brew this delicious beverage is the heating element. In this article, we will explore what tea kettle heating elements are, how they work and why they play a key role in the tea brewing process.

What are Teapot Heating elements?

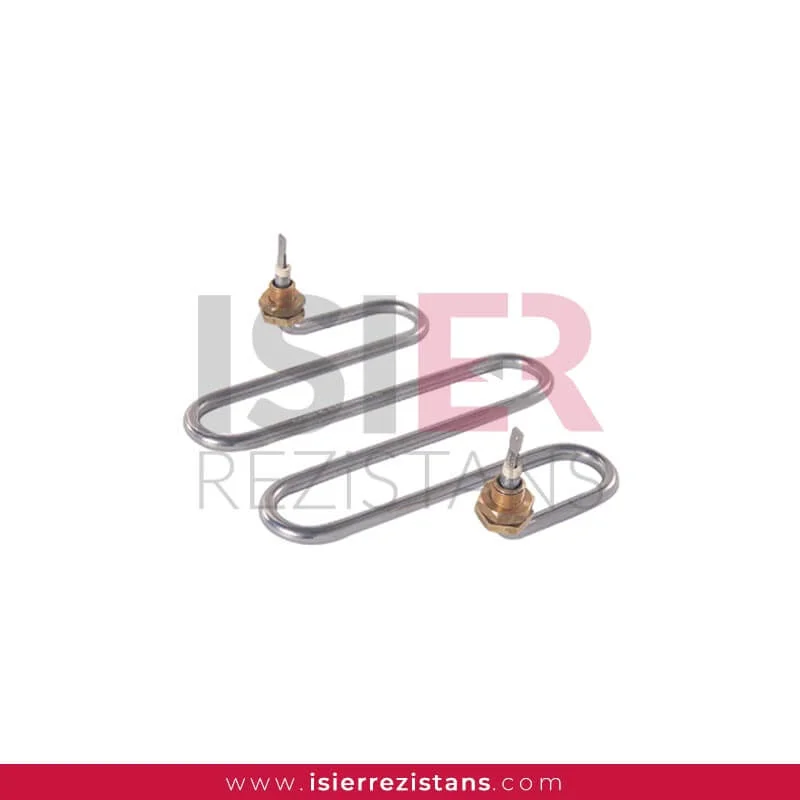

Teapot heating elements are electric heating elements used to heat tea water. They are made of stainless steel, nickel-chromium alloys or other heat-resistant materials. They are usually placed at the bottom of the teapot and boil the water by heating it with electrical energy.

Working Principle of Teapot Heaters

Teapot heaters basically work on the principle of resistance. When electric current is passed through the resistance, the resistance heats up and this heating heats the water and starts the boiling process. In this way, the water in the teapot reaches the brewing temperature and the tea is brewed by passing the steam to the tea leaves.

Technical Specifications of Teapot Heaters

Teapot heaters are heating elements with various technical specifications, determining the performance, durability, and ease of use of the heater. Here are the technical specifications of teapot heaters:

Material: Teapot heaters are typically made of heat-resistant materials such as stainless steel, nickel-chromium alloys, or titanium. Stainless steel provides durability and resistance to corrosion.

Power (Watt): The power of teapot heaters is usually expressed in watts. Power determines how quickly the heater will heat the water. For example, power values such as 1500W or 2000W can be used.

Voltage: Most teapot heaters operate at the standard household voltage of 220V or 230V. However, there may be situations in industrial applications where different voltages are required.

Size and Shape: Teapot heaters can come in different sizes and shapes. Different models designed to fit teapot designs are available. They can be tubular, spiral-shaped, or have special designs.

Durability and Waterproofing: High-quality teapot heaters should be resistant to water. Additionally, durability can be enhanced by using stainless steel or special coatings.

Ease of Installation: The installation of teapot heaters should be designed to allow easy integration into teapots. Standard mounting points and installation instructions facilitate this process.

Temperature Control: Some teapot heaters may be equipped with integrated temperature sensors or thermostats. This feature ensures that the water is maintained at a specific temperature.

Safety Features: Teapot heaters may have safety features to prevent overheating and ensure safe use. Features such as automatic shut-off or protection against overheating enhance user safety.

Compatible Teapot Models: Teapot heaters may include various designs to accommodate different teapot models. This allows users to select heater models that are compatible with their existing teapots.

Heat Distribution: High-quality teapot heaters provide homogeneous heat distribution. This ensures that the water is evenly heated, resulting in a more delicious tea.

These technical specifications are factors that determine the overall performance of teapot heaters. Users should pay attention to the technical specifications of teapot heaters when selecting a teapot.

In Which Sectors Are Tea Machine Heaters Used?

Tea machine heaters, commonly used in commercial and industrial sectors, are heating elements that contribute to the efficient operation of tea machines by quickly and effectively heating water. Here are some sectors where tea machine heaters are used:

Restaurants and Cafes: Restaurants and cafes often use large-capacity tea machines for tea service. Tea machine heaters meet high demand by quickly heating water in these machines.

Hospitality Industry: Hotels, resorts, and other accommodation facilities typically use tea machines for serving tea to guests. Tea machine heaters are ideal for extensive use in these facilities.

Meeting and Conference Centers: Tea service may be provided to participants during business meetings or conferences. Meeting venues require tea machine heaters for quick and convenient tea service.

Offices and Workplaces: Tea machines are commonly used in kitchen areas or break rooms in offices. Workplaces offering tea to employees or visitors can easily heat water with tea machine heaters.

Catering Services: Companies providing catering services for special events, weddings, meetings, or other gatherings often use tea machines. Tea machine heaters have the capacity to serve tea to large groups.

Hospitals and Healthcare Facilities: Tea machines may be used in hospital kitchens or staff break areas. Tea machine heaters are used to meet the tea needs in healthcare facilities.

Educational Institutions: School cafeterias or dining areas on university campuses may use tea machines to serve tea to students and staff. In this case, tea machine heaters have the capacity for quick tea service to a large student and staff population.

Public Transportation Vehicles: Tea machines with tea machine heaters can be used for tea service on airplanes, trains, buses, and ships.

Tea machine heaters are typically designed to be fast, reliable, and suitable for heavy usage. With these features, they are widely preferred in various sectors.

Why Should We Prefer Teapot Heaters?

Teapot heaters are important components used to ensure quick and effective brewing of tea. There are several significant reasons for choosing these heaters:

Fast Heating: Teapot heaters accelerate the brewing process by quickly heating the water. This feature allows users to enjoy their tea in a shorter amount of time.

Energy Efficiency: High-quality teapot heaters effectively heat water while using energy efficiently. This results in energy savings and reduced electricity costs.

Durability: Teapot heaters made from durable materials such as stainless steel or special alloys are long-lasting and resilient. This helps maintain performance during regular use.

Preservation of Water Quality: Quality teapot heaters reduce mineral buildup in the water, extending the lifespan of both the heater and the teapot. Additionally, they help preserve water quality, contributing to a tastier tea.

Easy Installation and Maintenance: Teapot heaters are typically easy to install and maintain. Standard connection points and user-friendly designs allow users to set up and maintain their teapots easily.

Variety of Models and Compatibility: Teapot heaters come in various designs to fit different teapot models. This allows users to choose heater models that are compatible with their existing teapots.

Safety Features: Some teapot heaters come with safety features such as overheat protection or automatic shut-off. This helps users use the teapot safely.

Affordability: Teapot heaters generally offer cost-effective and economical options. This reduces maintenance and repair costs for teapots.

Suitability for Various Applications: Teapot heaters can be designed to provide suitable temperatures for different types of tea and brewing methods. This offers a variety of tea enjoyment options.

These advantages of teapot heaters allow users to enjoy their tea more conveniently, quickly, and efficiently.