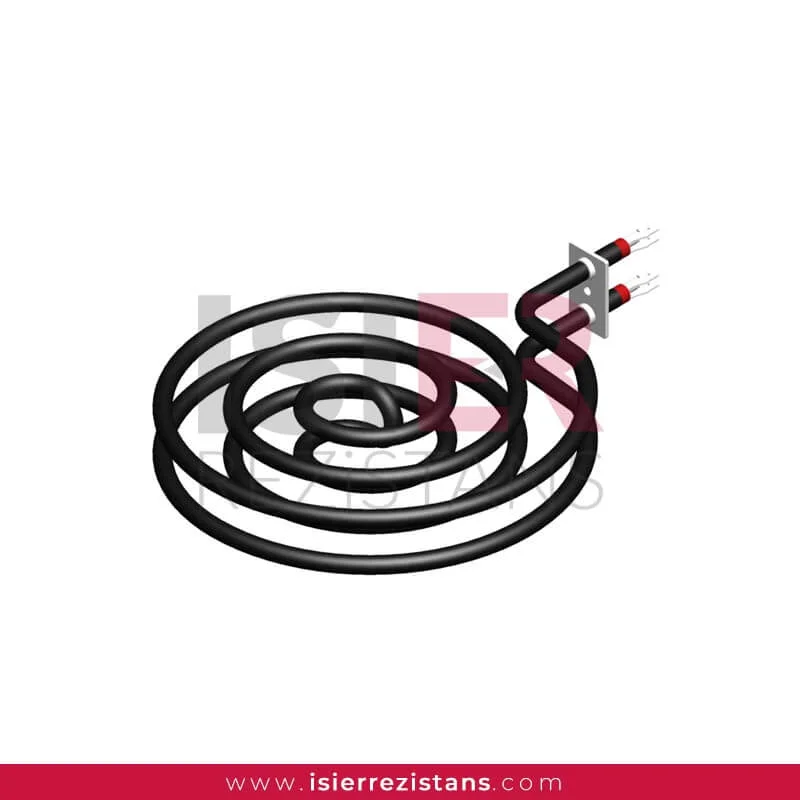

Spiral Heaters

Spiral heating elements are a special type of heating element used in many heating applications. It is a spiral-shaped heating element consisting of a wire wound around a material, usually in the form of a tube or cylinder. This design ensures uniform heat distribution and is a preferred feature in many industrial processes.

What are the Technical Specifications of Spiral Heaters?

Coil heaters are heating elements used in many industrial applications. The main technical specifications of coil heaters are as follows:

Material Selection: The material used in the manufacture of coil heaters is typically high-temperature resistant materials such as stainless steel, nickel-chromium alloys, or Fe-Cr-Al alloys. Material selection affects the durability, corrosion resistance, and overall performance of the heater.

Wire Diameter and Number of Spirals: The diameter of the wire and the number of spirals contained in the heater determine its total heat-generating capacity. Thicker wires and more spirals may indicate a heater with a higher power capacity.

Spiral Diameter and Length: The diameter and length of the spirals in coil heaters determine the overall size of the heater. These characteristics determine how the heater will be positioned in a specific area and how it will be designed to meet application requirements.

Power Capacity: Power capacity specifies the maximum heat power that a coil heater can produce within a certain period. This is important for evaluating whether the heater is suitable for a specific application.

Voltage Value: The operating voltage of the heater is important for its safe use. It is generally expressed in volts (V).

Resistance Value: The resistance value of the heater varies depending on the material and dimensions of the wire inside it. This value determines how much resistance the heater exhibits under a specific voltage.

Operating Temperature: It is important for the heater to operate safely within a specific temperature range. The operating temperature is determined based on the conditions the heater may be exposed to.

Protective Coating: A protective coating can enhance the heater’s resistance to corrosion and increase its durability. Stainless steel or other special coatings may be used.

Integration Capability: Coil heaters should be capable of being integrated into different heating systems and applications. This allows the heater to adapt to a wide range of applications.

Ease of Installation: Heater installation should be considered to facilitate application processes and make maintenance more accessible.

These technical specifications are critical factors to consider for effective use of coil heaters in various industrial applications. Coil heaters selected according to application requirements can provide high performance, durability, and long life.

Why Should Spiral Heaters be Preferred?

Coil heaters are preferred heating solutions in many industrial applications due to a variety of advantages. Here are some important reasons why coil heaters are preferred:

Homogeneous Heat Distribution: Coil heaters provide homogeneous heat distribution thanks to their spiral design. This ensures even heating of the material to be heated, thereby improving product quality and ensuring a stable production process.

High Power Capacity: Coil heaters designed with thick wires and a high number of spirals have a high power capacity. This provides an effective solution for industrial applications requiring rapid heating processes and high heat generation.

Compatibility with Various Materials: Coil heaters can be designed to be compatible with different materials. They can meet various application requirements using materials such as stainless steel, nickel-chromium alloys, or Fe-Cr-Al alloys.

Application Flexibility: Coil heaters provide flexibility for a wide range of applications. They can be used in many sectors, from the plastics and rubber industry to metal processing facilities, food production, and the chemical industry.

Durability and Longevity: Coil heaters made from high-quality materials provide durability and longevity. This reduces maintenance requirements and increases the continuity of production processes.

Easy Installation and Maintenance: Coil heaters are typically easy to install and maintain. This feature ensures uninterrupted processes in manufacturing facilities.

Wide Range of Applications: Coil heaters cater to a wide range of applications. They can be used in various fields, from plastic extrusion to metal shaping, food cooking processes, and chemical reactor heating.

High Temperature Resistance: Coil heaters can reliably operate at high temperatures. This feature provides an advantage in applications where industrial processes occur at high temperatures.

Energy Efficiency: Homogeneous heat distribution and high power capacity enable coil heaters to use energy more efficiently.

All these advantages make coil heaters a preferred option in industrial heating applications. With their adaptable designs and wide application areas, coil heaters offer a reliable, durable, and effective heating solution.

In Which Sectors Are Spiral Heaters Used?

Coil heaters are used in many industrial sectors due to their wide range of applications. Here are some industries where coil heaters are commonly used:

Plastics and Rubber Industry: Used for heating and shaping materials in extrusion machines, injection molding machines, and other plastic processing equipment.

Metal Processing Industry: Used for heating and processing metal materials in metal shaping machines and heat treatment furnaces.

Food Industry: Used in ovens, stoves, and other food production equipment for cooking and heating materials.

Chemical Industry: Used for heating various materials in chemical reactors and other chemical processes.

Automotive Industry: Used in paint drying ovens and other heat treatment applications for processing automotive parts.

Electronic Industry: Used for heating materials in electronic manufacturing processes, soldering stations, and testing equipment.

Energy Production and Plants: Used for heating water or other liquids in boiler systems and energy production facilities.

Packaging Industry: Contributes to packaging production processes by heating and shaping packaging materials.

Agriculture and Livestock: Used for heating water in agricultural facilities, heating animal shelters, and other agricultural applications.

Paper and Pulp Industry: Used for drying paper in paper production machines and other paper processing equipment.

Heating, Ventilation, and Air Conditioning (HVAC): Used for generating hot air in HVAC systems and heating devices.

Maritime and Shipbuilding: Provides heating for water or other liquids in the shipbuilding industry, marine vessels, and maritime applications.

Coil heaters are preferred in these industries due to their advantages such as homogeneous heat distribution, high power capacity, and wide application flexibility. Offering different application areas in each sector, coil heaters provide a reliable solution in industrial heating systems.