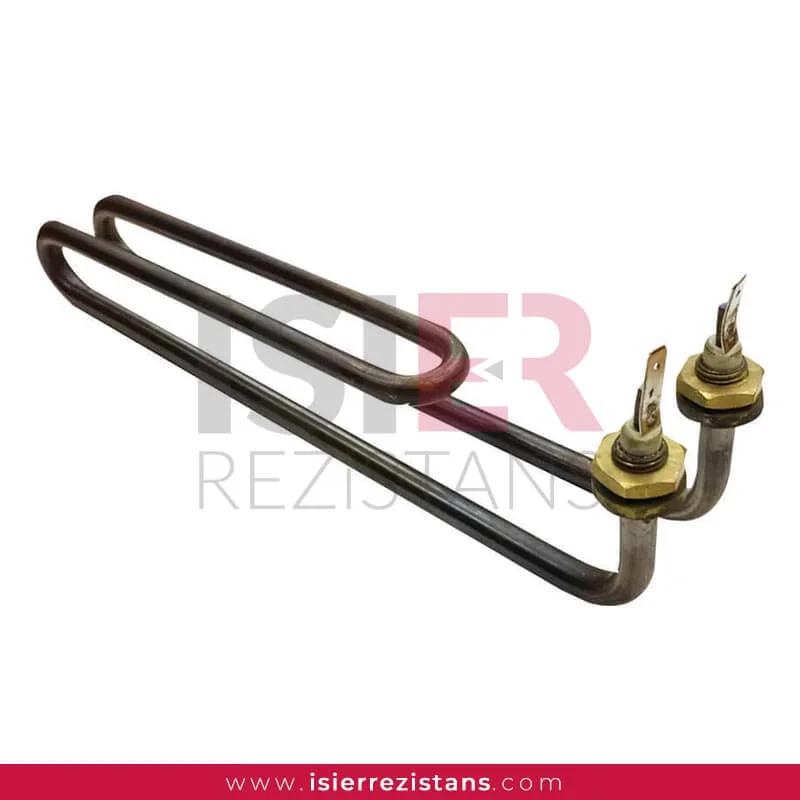

Pot Heaters

Teapot and pot heating elements are heating elements equipped with special design and technology. These heating elements optimize the brewing process by quickly heating the water in the teapots and pots. This ensures that the tea is brewed at optimum temperature and flavor.

How Do Pot Heaters Work?

The heater elements in the tea kettle and pot utilize the resistance of water to generate heat. As electrical energy passes through the heater, it increases the kinetic energy of water molecules, thereby heating the water. Through control units, temperature sensitivity is ensured, allowing the water in the tea kettle or pot to reach the desired temperature level.

Heater elements in pots provide a modern and technological solution for the perfect brewing of tea. The special design and high-performance heaters by HeatTech are developed to enhance tea culture and professional kitchens. Tea kettle and pot heaters offer top-notch heating solutions to tea enthusiasts, restaurants, and professional kitchens like hotels, highlighting the quality tea experience.

What are the Technical Specifications of Pot Heaters?

Pot heaters are heating elements equipped with special design and technological features. The technical specifications of these heaters include various parameters that determine their performance. Here are the general technical specifications of pot heaters:

Power Capacity: The power capacity of pot heaters determines how much heat they can generate in a specific period. This value is expressed in watts (W). Pot heaters typically offer various power options, such as 1000W, 1500W, etc.

Voltage and Current Values: The operating voltage and current values of the heater are specified. These values are important to ensure compatibility with the electrical system used. For example, 220V or 380V.

Size and Shape: Pot heaters are produced in different sizes and shapes. The length is usually specified in millimeters. For example, 300mm or 400mm.

Resistance Value: The resistance value of the heater is expressed in ohms. This value determines how much resistance the heater exhibits under a specific voltage.

Temperature Range: The operating temperature range of pot heaters is specified. This is typically expressed in degrees Celsius (°C). For example, -50°C to 300°C.

Material: The materials used in the construction of pot heaters are typically high-temperature resistant alloys or specially coated materials.

Protection Class (IP Rating): The IP class indicating the resistance of the heater to water and dust is specified. For example, IPX4.

Connection Type: The connection type of pot heaters is specified. This affects the mounting and integration of the heater. It can be threaded, flanged, or other special connection types.

Control and Regulation: Some pot heaters come with an integrated control unit or thermostat. This control unit is used to determine and control temperature values.

Heating Element Type: Depending on the design of the pot heater, it can have different types of heating elements such as steam tube, immersion type, or coil.

Ease of Installation: Pot heaters should be easy to install and user-friendly. This simplifies the integration process of the device.

Compatibility and Certification: Pot heaters may comply with specific industry standards or certifications.

These technical specifications demonstrate that pot heaters are designed to be compatible with various pot models and can be diversified to be integrated into different application areas.

Why Should Pot Heaters be Preferred?

Heater heaters are preferred in many applications due to various advantages. Here are the reasons for the preference of heater heaters:

Rapid Heating: Heater heaters quickly heat water, rapidly heating the liquid or contents inside. This provides users with quick usage.

Precise Temperature Control: Heater heaters provide precise temperature control thanks to integrated sensors and control systems. This feature automatically shuts off when a certain temperature level is reached, preventing overheating.

Energy Efficiency: Heater heaters offer high energy efficiency, saving energy and minimizing usage costs.

Longevity and Durability: Heater heaters, made with quality materials, are long-lasting and durable. This reduces maintenance requirements and increases the product’s lifespan.

Various Application Areas: Heater heaters can be designed to fit various pot models, meaning they can be integrated into different application areas.

Easy Installation: Thanks to user-friendly designs, heater heaters are suitable for easy installation and disassembly. This allows users to easily maintain their devices.

Wide Technical Specifications: Heater heaters can be offered with a wide range of technical specifications. This allows them to adapt to various usage needs.

Various Size and Power Options: Heater heaters offer different size and power options, accommodating various pot models. This provides users with more choices and flexibility.

Safety Features: Heater heaters provide safety features such as automatic shutdown in case of overheating, thanks to integrated safety sensors.

Versatility in Various Industries: Heater heaters can be used in various industries, from household use to restaurants, industrial kitchens to laboratories.

These advantages make heater heaters appeal to a wide range of applications, leading many users to prefer them.

In Which Sectors Are Pot Heaters Used ?

Heater heaters are versatile heating elements with a wide range of applications across various industries. Here are some sectors where heater heaters are commonly used:

Gastronomy and Restaurants: Heater heaters are used in restaurants for cooking and preparation tasks. They are particularly preferred for boiling water and cooking in large pots.

Hospitality and Accommodation: In hotel kitchens, especially at breakfast buffets, heater heaters are used to boil large quantities of water or prepare hot beverages.

Industrial Kitchens: In large kitchens, industrial heater heaters provide effective heating for cooking in large pots and other industrial kitchen operations.

Food Processing and Manufacturing: In food processing facilities, heater heaters quickly heat large quantities of water to assist in processing and packaging products.

Chemistry and Laboratories: In chemistry laboratories, heater heaters are used to control reactions at specific temperature conditions and to heat liquids used in experiments.

Hospitals and Healthcare Facilities: In healthcare facilities, heater heaters can be used to sterilize large quantities of water or prepare hot beverages for patients.

Agriculture and Horticulture: In greenhouse farming, heater heaters are used to heat large volumes of water used for seeding or cultivating plants.

Entertainment and Events: At large events or in the entertainment sector, heater heaters are used to prepare large quantities of beverages. Concerts, fairs, and event venues are examples of such sectors.

Maritime and Ships: In the maritime sector, heater heaters in ship kitchens are used to quickly heat large quantities of water for the needs of crew members and passengers.

Energy and Industry: In industrial processes, especially in large boilers or process tanks, heater heaters are used to heat large quantities of water or other liquids.

In these sectors, heater heaters are used as an effective solution to meet large-volume heating needs and efficiently heat water or other liquids.