Paper and Paperboard Manufacturing Heaters

Heaters are used in Paper and Cardboard Manufacturing for Various Purposes:

Drying Processes: In the production of paper and cardboard, it is crucial to control the moisture content of the materials. Heaters can be utilized for drying paper pulps or in coating processes.

Paper and Cardboard Pressing: Pressing and shaping the pulp are crucial stages in paper production. Heaters can be used to heat the presses during this stage.

Cardboard and Carton Production: In the production of cardboard and carton, heaters can be used in shaping, drying, and adjusting the thickness of the material.

Paper Coating and Lamination: In some cases, paper or cardboard surfaces may need to be coated or laminated. Heaters can be used for heating during these processes.

Paper and Cardboard Cutting: During the cutting process in paper and cardboard production, heaters can be used to heat the edges of the material, allowing for smoother and more precise cuts.

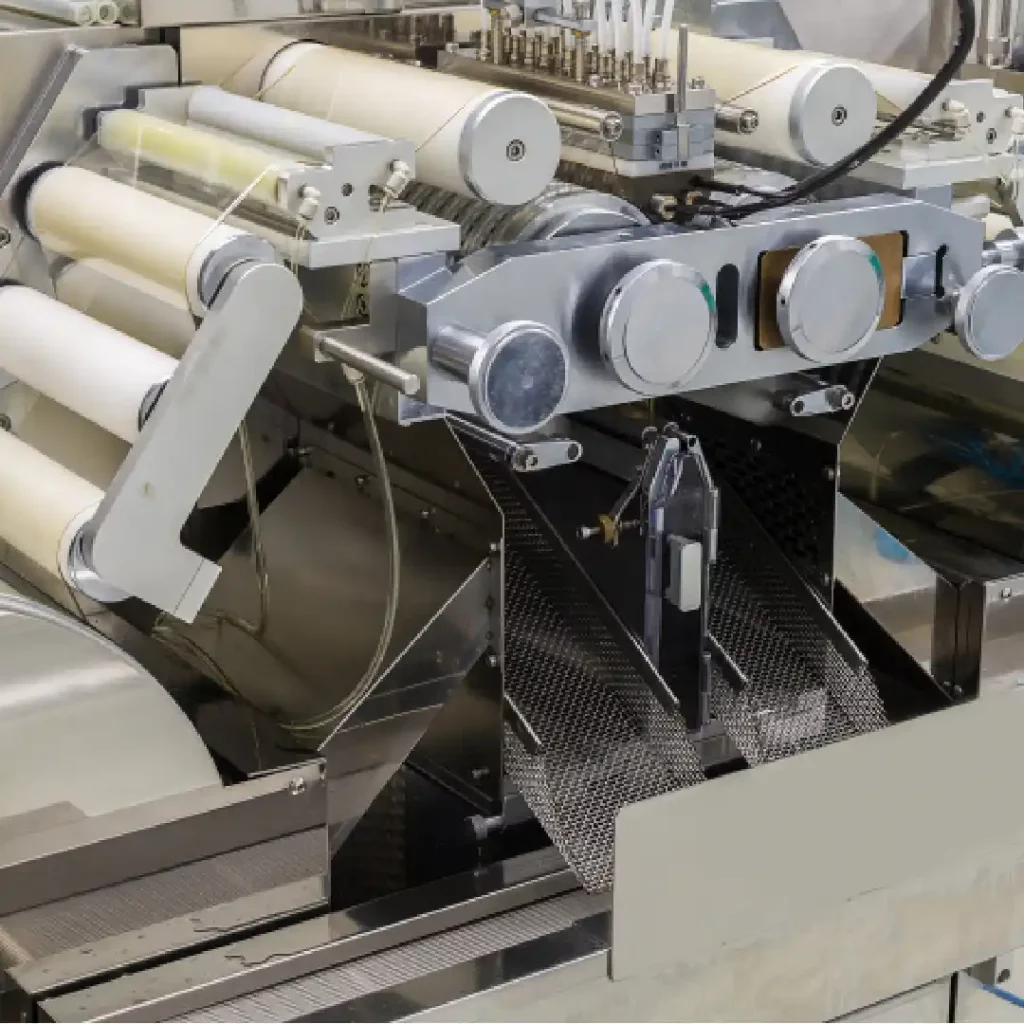

Roll Heating Systems: Heaters can be employed for heating and controlling the rollers used in paper and cardboard production.

Heaters play a significant role in providing temperature control and heating in these processes, ensuring that the materials are produced to the desired quality standards. Additionally, factors such as moisture control and determining the form of the material may also necessitate the use of heaters.

Our Products

Your Solution Partner for All Your Resistance Needs

The Importance of Heaters in Paper and Paperboard Manufacturing

The use of heaters in paper and cardboard manufacturing provides a range of significant advantages, contributing to more efficient, controllable, and high-quality production processes. Here are some factors explaining the importance of heaters in paper and cardboard manufacturing:

Heating and Drying: Heating is necessary for drying and shaping materials in paper and cardboard production processes. Heaters expedite these heating processes, aiding in accelerating production and achieving the desired form and quality of the material.

Moisture Control: Moisture control is critical in paper and cardboard production. Heaters are used to control the moisture content of materials and reach desired humidity levels.

Quality Control: Heaters ensure temperature control during production processes, enabling the materials to be manufactured to the desired quality standards.

Energy Efficiency: Well-designed and utilized heaters can increase energy efficiency, thereby reducing production costs.

Quick Response and Control: Electric heaters can heat up and cool down rapidly, facilitating fast and precise temperature control.

Automation of Production Processes: Heaters, when integrated with automation systems, allow production processes to become more efficient and automatic.

Material Shaping and Pressing: Heaters can be used in shaping and pressing paper or cardboard materials, facilitating the attainment of the desired form and thickness of the material.

Product Quality: Proper use of heaters can optimize temperature control in production processes, enhancing product quality.

For these reasons, the use of heaters in paper and cardboard manufacturing contributes to making production processes more effective, efficient, and of higher quality, thereby contributing to industrial success.

Technical Specifications of Heaters Used in Paper and Paperboard Manufacturing

The technical specifications of heaters used in paper and cardboard manufacturing can vary depending on specific application requirements and the type of equipment to be used. However, we can generally focus on the following basic technical specifications, expressed with some numbers:

Nominal Power (Watt): The nominal power of heaters used in paper and cardboard manufacturing typically refers to their ability to operate at a certain temperature under a specific electric current. For example, a heater with a nominal power of 5000 Watts.

Nominal Voltage (Volt): The operating voltage of heaters should also be suitable for a specific application. For instance, a heater capable of operating at a nominal voltage of 220 Volts.

Resistance Value (Ohm): The resistance value of a heater indicates its resistance under a specific current at a certain temperature. For example, a heater with a resistance value of 10 Ohms.

Material: Heaters used in paper and cardboard manufacturing are generally made of materials resistant to high temperatures, such as nickel-chromium alloys or iron-chromium-aluminum alloys.

Temperature Range: The temperature range within which a heater can operate is crucial for a specific application. For example, a heater capable of operating between -20°C to 400°C.

Dimensions and Design: Heaters used in paper and cardboard manufacturing may come in specific dimensions and designs to fit certain equipment or applications. For example, a heater with dimensions of 50 cm in length and 5 cm in width.

Corrosion Resistance: It is important for heaters to be resistant to corrosion, especially if they will be used in damp or wet environments.

Cable Connections: Heaters should have appropriate cable connections to facilitate integration with equipment.

These technical specifications are fundamental factors that determine the performance of heaters used in paper and cardboard manufacturing. It is important to remember that specific heaters may vary in these specifications according to application requirements.

Technical Details to Consider in Paper and Paperboard Manufacturing Selection

During the selection of equipment in paper and cardboard manufacturing, attention to technical details influences the effectiveness, quality, and efficiency of production processes. Here are the technical details to consider when selecting equipment in paper and cardboard manufacturing:

Capacity and Efficiency: The daily or hourly capacity of the production line determines the required level of efficiency. The production capacity of the equipment should be in line with the demands of the operation.

Material Variety: It’s essential for the equipment used in paper and cardboard production to be compatible with different types of materials. Equipment capable of working with materials of varying thicknesses and properties should be preferred.

Processing Speed and Adjustability: The adjustability of processing speed enables the equipment to respond to different production requirements. Adjustable equipment provides flexibility and efficiency.

Energy Efficiency: The energy consumption and efficiency of the equipment affect operational costs. Energy-efficient equipment is crucial for sustainability and cost-effectiveness.

Installation and Maintenance Convenience: The equipment should be easy to install and maintain. Quick installation speeds up production processes, while regular maintenance ensures long-term use.

Spare Parts and Service Support: The equipment provider’s provision of spare parts and effective service support ensures that any faults can be quickly addressed.

Technological Compatibility and Integration: The equipment should be compatible with modern technology and easily integrated into operational processes, optimizing data collection and analysis processes.

Safety Standards and Compliance: Equipment compliance with safety standards is critical for occupational health and safety.

Environmental Sensitivity: Designing equipment to minimize environmental impact contributes to sustainable production processes.

Training and User-Friendly Interface: Facilitating operator training and providing a user-friendly interface help ensure smooth operations.

These factors are fundamental technical details to consider when selecting equipment in paper and cardboard manufacturing. Proper equipment selection contributes to the efficiency, safety, and cost-effectiveness of your production processes.

Cartridge Heaters Used in Paper and Paperboard Manufacturing Sector

In the paper and cardboard manufacturing sector, cartridge heaters typically refer to a type of heater commonly used in industrial heating applications. Cartridge heaters consist of heating elements usually in the form of coils or wires, housed within a metal cartridge. These heaters are particularly used in heating processes in industrial ovens, drying systems, pressing machines, and similar equipment.

Drying Processes: In paper and cardboard production, they can be used for drying materials, ensuring fast and effective drying.

Heated Roller Systems: Cartridge heaters can be used in heated roller systems used in production lines, providing heat as materials pass over them.

Pressing and Shaping: In paper and cardboard production, cartridge heaters can be used for heating during pressing and shaping processes.

Lamination Processes: They can be used for heating during lamination processes where paper and cardboard materials are brought together and bonded.

Gluing and Folding: In paper and cardboard production, they can be used for gluing or folding materials.

Custom Production Lines: In specially designed production lines for paper and cardboard production, cartridge heaters can be integrated to meet specific application requirements.

Cartridge heaters typically possess the ability to reach high temperatures and heat up quickly, making them suitable for various heating needs in paper and cardboard production. These heaters are widely used in industrial applications, providing precise temperature control and energy efficiency in production processes.