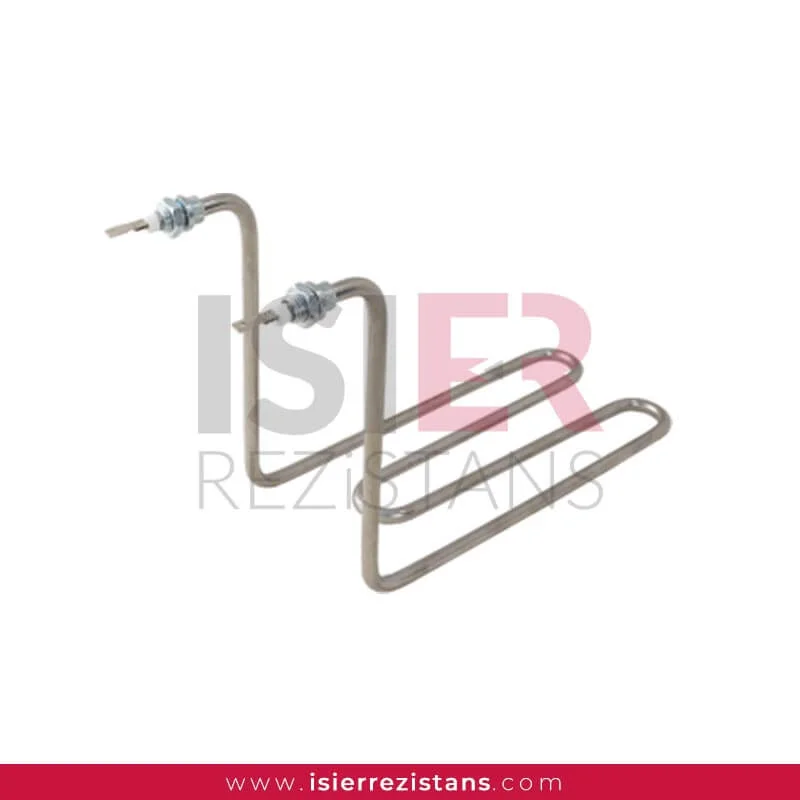

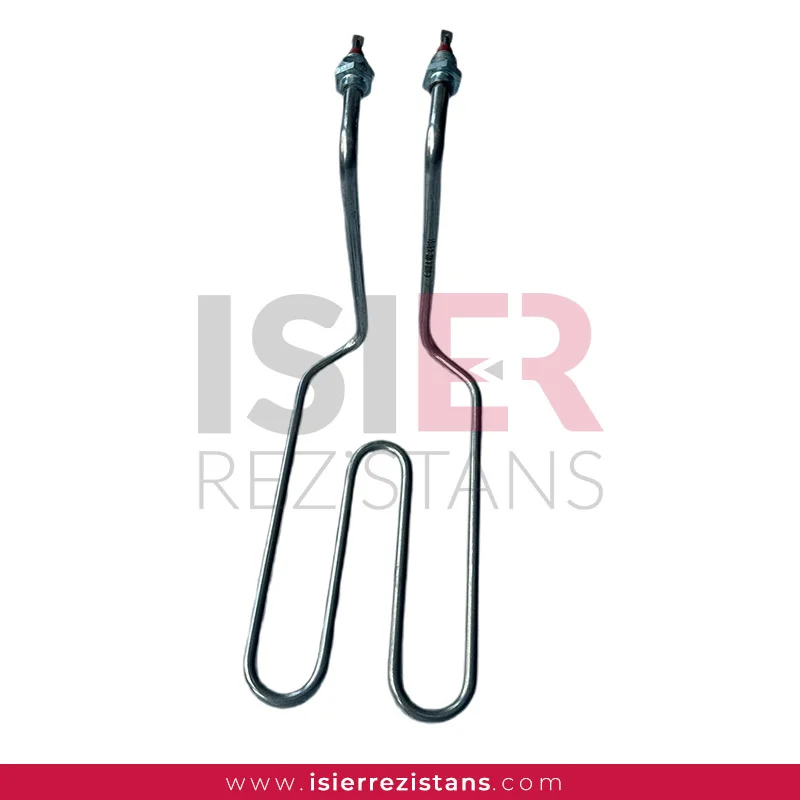

Fryer Heaters

Fryer heating elements are specially designed heating elements that are widely used especially in the food processing industry. These heating elements are specially manufactured for use in deep fryers and allow the oil to heat up quickly, allowing food to be fried to perfection.

What Do Fryer Heaters Do?

Heater elements, also known as fryer heaters, play a crucial role in the process of frying by rapidly and effectively heating the oil inside fryer devices. These heater elements are specially designed heating components with specific technical specifications. Here are the main functions of fryer heater elements:

Heating the Oil: Heater elements in fryers quickly heat the oil inside to bring it to a specific temperature range, ensuring that the oil is hot enough for frying foods.

Supporting the Frying Process: Fryer heater elements facilitate the quick and uniform frying of foods by heating the oil to the desired temperature, resulting in crispy exteriors and tender, flavorful interiors.

Temperature Control: Fryer heater elements are typically integrated with a control unit. This control unit is used to maintain and adjust a specific temperature level, ensuring the frying process occurs at the desired quality.

Increasing Energy Efficiency: High-quality fryer heater elements are designed to increase energy efficiency. Their fast heating and cooling features support energy savings.

Longevity and Durability: Fryer heater elements are made from durable materials to withstand frequent use, providing long-lasting performance and reducing maintenance needs.

Quick Response: Fryer heater elements can rapidly reach desired temperature levels and respond swiftly to temperature changes within the system, allowing businesses to operate more flexibly and efficiently.

Enhancing Food Quality: With rapid and uniform heating, fryer heater elements ensure that fried foods have crispy exteriors and delicious interiors, thereby enhancing food quality.

Heater elements are commonly used in the food industry, restaurants, fast-food chains, and other commercial kitchens to contribute to effective and delicious frying processes.

What are the Uses of Fryer Heaters?

Fryer heaters are specially designed heating elements commonly used in frying processes, especially in the food industry. These heaters take on the task of rapidly and effectively heating the oil to fry food items. Here are the usage areas of fryer heaters:

Restaurants and Cafés: Fryer heaters are widely used in restaurant and café kitchens. Their fast heating features enable quick service during busy hours.

Fast Food Chains: In fast-food restaurants, heaters in large-scale fryer systems support fast and efficient frying processes.

Food Production Facilities: Fryer heaters are used in food production facilities, especially where ready-to-eat food products and snacks are manufactured.

Supermarkets and Grocery Stores: Heaters are preferred in small-scale fryers used in supermarkets and grocery stores offering ready-to-eat fried products.

Hotels and Accommodation Facilities: Fryer heaters can be used in hotels and accommodation facilities with large kitchens, breakfast buffets, or restaurants.

Food Factories: Heaters in industrial fryer systems in large-scale food production factories meet intensive production needs.

Airports and Passenger Catering: Fryer heaters can be used in airports and passenger catering establishments to meet fast service requirements.

Entertainment and Theme Parks: Fryer heaters are commonly used in fast-food outlets in large entertainment complexes or theme parks.

School and University Cafeterias: Fryer heaters can be used in school cafeterias and university campuses with kitchens catering to large student populations.

Hospitals and Healthcare Facilities: Fryer heaters can be used in hospital kitchens or healthcare facilities for patient and staff meals.

These usage areas demonstrate that fryer heaters are widely preferred in various commercial kitchen and food processing environments. They provide an important heating solution for fast, efficient, and delicious frying processes.

Why Should You Prefer Fryer Heaters?

Fryer heaters are preferred in the food processing industry and commercial kitchens due to a variety of advantages. Here are the reasons why fryer heaters are chosen:

Rapid Heating and Cooling: Fryer heaters accelerate frying processes by quickly heating the oil due to their high power capacity. Additionally, their quick cooling feature enhances energy efficiency once the process is complete.

Energy Efficiency: Fryer heaters designed with high energy efficiency help businesses reduce their energy costs.

Long-lasting and Durable Materials: Fryer heaters are typically constructed from stainless steel or special alloys to ensure longevity and durability, thereby enhancing the resilience of kitchen equipment.

High Temperature Tolerance: Constructed from materials resistant to high temperatures, fryer heaters adapt to intense frying processes and conditions involving hot oil exposure.

Flexible and Customizable Design: Fryer heaters can be customized in various sizes and shapes to accommodate different fryer models and needs.

Hygiene and Easy Cleaning: The use of stainless steel materials ensures that fryer heaters are hygienic and easy to clean, supporting food safety and operational standards.

Quick Response and Control: Fryer heaters can quickly reach desired temperature levels and respond rapidly to temperature changes, assisting businesses in achieving precise control.

Various Application Areas: Fryer heaters can be integrated into fryer models of different sizes, allowing them to be used in various kitchens and food processing facilities.

All these advantages make fryer heaters a reliable, effective, and cost-saving heating solution for businesses.

What are the Technical Specifications of Fryer Heaters?

The technical specifications of fryer heaters encompass various parameters that determine the performance of these heating elements. Here is a detailed list explaining the technical specifications of fryer heaters:

Material: Fryer heaters are typically made of heat-resistant materials such as stainless steel, nickel-chromium alloy, or special alloys. Stainless steel is suitable for hygienic conditions.

Power Capacity: Power capacity determines how much heat the heater can produce in a specific period and is expressed in watts (W). For example, 2000W or 3000W.

Voltage and Current Values: The operating voltage and current values of the heater are specified. These values are important to ensure compatibility with the electrical system used. For example, 220V or 380V.

Size and Shape: Fryer heaters can be produced in various sizes and shapes. The length is usually specified in millimeters (e.g., 400mm or 500mm).

Resistance Value: The resistance value of the heater is expressed in ohms. This value determines how much resistance the heater exhibits under a specific voltage.

Temperature Range: The operating temperature range of fryer heaters is specified. For example, it can be expressed as -20°C to 300°C.

Protection Class (IP Rating): The IP class indicating the resistance of the heater to water and dust is specified. For example, IPX4.

Connection Type: The connection of fryer heaters to the fryer can be nutted, flanged, or of other special types.

Heating Element Type: Depending on the design of the heater, it can be of different types such as steam tube, immersion type, or coil.

Control and Regulation: Some fryer heaters come with an integrated control unit or thermostat, allowing precise temperature control.

Special Coatings and Materials: Some heaters can be coated with special coatings or materials, enhancing durability or adapting to specific conditions.

Ease of Installation: Fryer heaters should be easy to install. Nutted, flanged, or other mounting options may be available.

These technical specifications indicate that fryer heaters are designed to meet various application needs and can be integrated into a specific fryer model or industrial frying system to optimize performance.