Clamp Heaters

Clamp Heaters; it is resistance that can be used in environments with high temperatures. These resistors, which are frequently used in different workplaces, are products with high durability up to 800 degrees.

Our Clamp Type Heaters products are produced from alumsinian steel or special galvanized. It is also extremely resistant to expansion and yawning problems. Clamp Heaters models are generally preferred in the heavy industry thanks to their durable structure.

Clamped Heaters, which have a wide range of uses, can be produced in different shapes and models according to their functional characteristics.

Techincal Information

High quality Clamp Heaters are manufactured for high heat-requiring working applications and areas. Clamp Heaters, which are also used easily at the highest temperatures, are among the products that manage to appeal to different uses

Clamp Heaters are produced in 3 different models based on working principles:

Mika Insulated Clamp Heaters

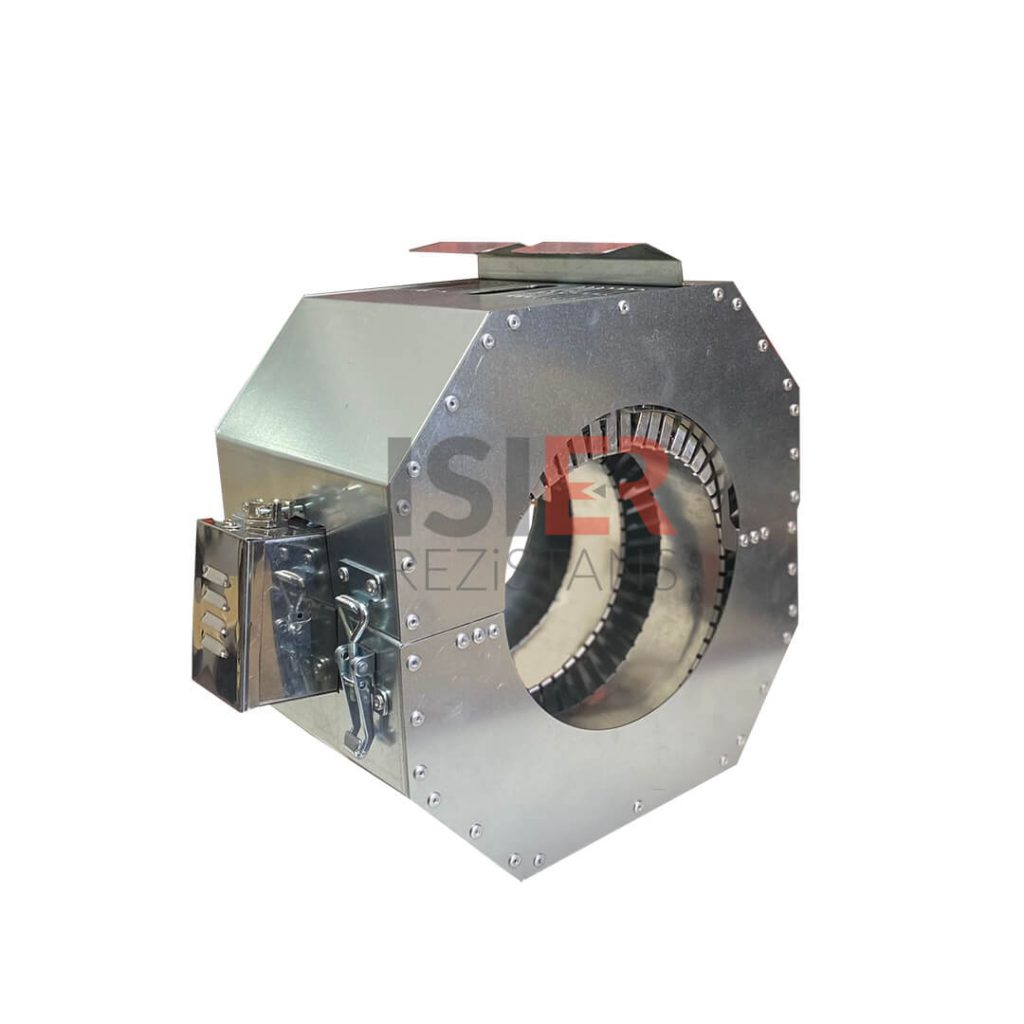

Mica insulated Clamp Resistance models are used efficiently in the shaping and projecting of plastic raw materials, especially in extruder, injection type plastic machines in areas with a working temperature of up to 300°C. In addition, it is widely used in heating tanks of different sizes of many pipelines. Mica Insulated Clamp Resistors are frequently used in industrial areas due to their affordable cost.

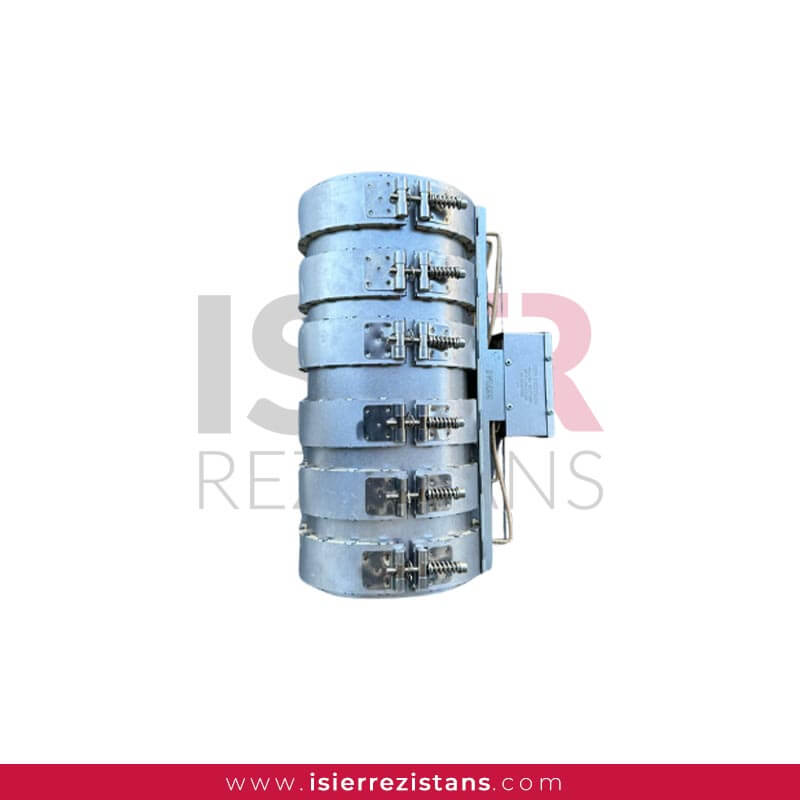

Ceramic Clamp Heatres

Ceramic Clamp Resistors, one of the most durable types of clamp resistors, can be easily used in applications up to 650°C. The most important feature that allows ceramic resistors to reach such high temperatures are steatite alloy ceramics used to insulate the resistance wire. The main uses of Ceramic Clamp Resistors are; In addition, ceramic Clamp Resistors are frequently used in heating pipelines, various tanks and special projects by spraying from the outside, which requires high temperature and high power. The energy outputs of ceramic clamp resistors are produced with Klemensli – Closed Box Clamp – Wired – Iron plug output.

Clamp Heaters Models

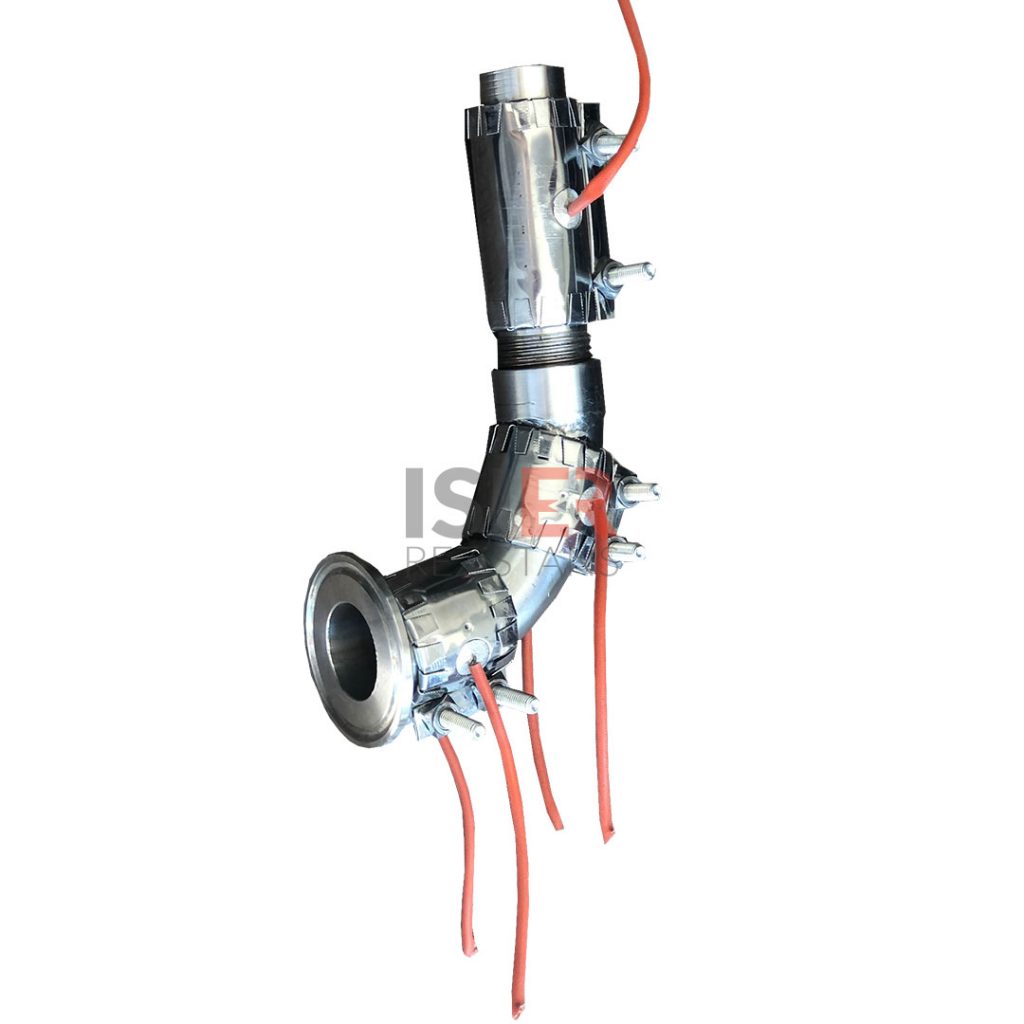

Square type or flat rectangular pipe heaters manufactured with thin cross-section closed circuit production technique applied to stainless steel as an outer sheath can be produced by placing. Since such resistance models include a closed circuit system, they can be easily used in places with moisture, steam, humidity and liquid fluidity. The probability of failure of these products due to the above handicap reasons is very low. In addition, such Clamp Resistance models can be easily used in areas with a maximum thermal environment of 500 °C.

What is Clamp Heating?

Clamp heating element is a heating system powered by electric current. This heating system generates heat by electric current passed through a metal component and spreads the heat to the targeted area thanks to its clamp-shaped structure.

Technical Specifications of Clamp Heaters

Clamp heaters may have the following technical specifications:

Operating Voltage: Typically ranging from 110V to 240V.

Operating Current: The amount of electrical current required for operation.

Heating Area: The size of the area to be heated.

Heat Output: The amount of heat produced relative to the energy consumed.

Dimensions: The length, width, and thickness of the clamp heater.

Mounting Options: How the clamp heater can be mounted (flat, circular, etc.).

Material: The type of material used in the construction of the clamp heater (nickel alloy, brass, etc.).

Temperature: The maximum operating temperature of the clamp heater.

Usage Areas of Clamp Heaters

Clamp heaters can be used in various industrial and residential applications. Some of the areas where clamp heaters are utilized include:

Industrial: Plastic molding, painting and coating, metal processing, mold heating.

Residential: Water heaters, water tanks, water filter heating.

Automotive: Engine temperature control, heating of oil and clutch fluid.

Chemical and Petroleum Industry: Reactor heating, separation of solid-liquid solutions, solution heating.

What is a Ceramic Clamp Heater?

Ceramic Clamp Heaters refer to the electrical resistance of a ceramic material when subjected to mechanical compression or pressure. This term is typically used in the context of electrical engineering and materials science and defines the ability of a ceramic material to resist the flow of electrical current when clamped or compressed.

The resistance of a ceramic material can be influenced by various factors including the composition and microstructure of the material, the type of ceramic, the presence of impurities, and the applied clamping force. The ceramic clamp resistance of a material can be an important factor in determining its suitability for use in electrical and electronic applications such as the production of capacitors, resistors, and other components.

Ceramic Clamp Heaters Technical Specifications

The characteristics of ceramic clamp heaters can vary depending on the manufacturer and the specific product, but some general features include:

Resistance value: The resistance of the heater, typically measured in ohms.

Tolerance: The amount by which the resistance can deviate from the nominal value, expressed as a percentage.

Power rating: The maximum power that the heater can safely dissipate, typically measured in watts.

Operating temperature range: The range of temperatures within which the heater can be safely used.

Temperature coefficient of resistance (TCR): The rate at which the resistance of the heater changes with temperature, typically measured in parts per million per degree Celsius (ppm/°C).

Insulation resistance: The resistance of the insulation surrounding the heater, typically measured in megaohms.

Voltage rating: The maximum voltage that the heater can withstand, typically measured in volts.

Size: The physical dimensions of the heater, typically specified as length, width, and height.

Termination type: The type of connection used to attach the heater to a circuit, such as wire leads or surface-mount pads.

Dielectric strength: The maximum voltage that the insulation surrounding the heater can withstand before breaking down, typically measured in volts.

Uses of Ceramic Clamp Heaters

Ceramic clamp heaters, also known as ceramic clamp heaters, are used in various industrial and commercial applications where a heat source is required. Some common uses of ceramic clamp heaters include:

Plastic processing: Heating molds to create plastic parts.

Packaging industry: Heating surfaces for bonding and cutting packaging films.

Food and beverage industry: Heating tanks, pipes, and other equipment for processing and storing food and beverage products.

Medical industry: Sterilizing medical instruments and equipment.

Printing industry: Heating printing plates and drying ink.

Textile industry: Heating textile machinery and equipment.

Chemical industry: Heating chemical tanks and reactors.

Clamp Heaters

Clamp heaters are effective resistance systems used in environments requiring high temperatures. Widely preferred in industrial areas, these specific heaters can provide high durability up to 800 degrees. Our clamp-type heaters are manufactured from aluminum steel or special galvanized materials, making them highly resistant to issues such as expansion and contraction.

One of the main reasons clamp heaters are frequently used in heavy industrial industries is their robust structure along with their wide range of applications. These heaters can be produced in various shapes and models depending on their functional features. For instance, they are utilized in industrial ovens, plastic processing machines, the automotive sector, and many other fields.

Known for their durable structure, clamp heaters offer reliable performance in high-temperature environments and ensure long-lasting use. Additionally, they are available in various sizes and power options, making them suitable for a wide range of applications to meet different requirements. With these features, clamp heaters have become a preferred solution for many businesses in industrial processes.

Technical Information of Clamp Heaters

High-quality Clamp Heaters are typically specially manufactured for industrial applications and areas requiring high temperatures. These clamp heaters are products that can be safely used even at the highest temperature degrees and can meet various industrial needs.

Clamp Heaters are produced in three different models:

Mica Insulated Clamp Heaters: Mica insulated clamp heaters are commonly used in areas requiring temperatures up to 300°C. They are efficiently used in shaping and molding plastic raw materials, especially in extrusion and injection-type plastic processing machines. Additionally, they are widely preferred for heating various pipeline systems and tanks of different sizes. Due to their cost-effectiveness, mica insulated clamp heaters are frequently used in industrial areas.

Ceramic Clamp Heaters: Ceramic clamp heaters are one of the most durable types of clamp heaters and are generally used in applications requiring temperatures up to 650°C. An important feature that makes ceramic heaters resistant to high temperatures is the steatite alloy ceramics used to insulate the resistance wire. These types of heaters are commonly used in areas where plastic raw materials are shaped and melted. Moreover, they are preferred in pipelines, various tanks, and special projects requiring high temperatures and high power. Energy outputs of ceramic clamp heaters can be produced with terminal block, closed box terminal block, cable, or iron plug outputs.

Clamp Heater Models: Square or flat rectangular tube heaters manufactured by the thin-sectioned closed circuit production technique placed inside stainless steel outer casing can be safely used in environments with moisture, steam, humidity, and liquid flow. These types of heater models offer reliable performance by minimizing the possibility of malfunctions. Additionally, these products, which can be used at a maximum temperature of 500°C, are preferred in various industrial applications.

Usage Areas of Clamp Heaters

Clamp heaters have a wide range of applications and can be effectively used in many industrial and domestic settings. Here are more detailed areas of use for clamp heaters:

Industrial Applications:

– Plastic Molding: Used in plastic injection machines, extrusion machines, and other plastic shaping processes. They provide heating for melting and shaping plastic materials.

– Painting and Coating Industry: Used in paint drying ovens, industrial drying facilities, and other painting and coating applications.

– Metal Processing: Used for shaping, forging, or hardening metal parts.

– Mold Heating: Used for heating molds in molding processes.

Domestic Applications:

– Water Heaters: Used in water heaters for producing hot water.

– Water Tanks: Used for heating the water inside water tanks and storing hot water.

– Water Filter Heating: Can be used to prevent the freezing of water in water filters.

Automotive Applications:

– Engine Temperature Control: Used to prevent engine freezing in cold weather and ensure optimal operating temperature.

– Heating of Oil and Clutch Fluid: Used to reduce the viscosity of oil and clutch fluids in cold weather and facilitate faster engine warming.

Chemical and Petroleum Industry Applications:

– Reactor Heating: Can be used in reactors to accelerate chemical reactions or maintain them at specific temperatures.

– Separation of Solid-Liquid Solutions: Used in industrial filtration and separation processes.

– Solution Heating: Used in chemical processes to heat solutions and carry out reactions.

Clamp heaters, used in these and similar applications, can increase the efficiency of industrial processes while also providing energy and cost savings.