Bainmari Heaters

Heaters are electric heating elements used in cooking processes using a water bath or bain-marie method. These heaters are typically placed inside specially designed containers and used by adding water into them. The bain-marie method provides precise control and homogeneous heat distribution, allowing dishes to be cooked at low and steady temperatures.

Working Principle

Electric Current: Bain-marie heaters are heating elements that operate with electric current. Electric current passes through the heater, causing it to heat up.

Water Bath: Bain-marie heaters are typically placed inside specially designed containers. Water is added into these containers. The water absorbs the heat from the heater and slowly transfers this heat to its surroundings, providing homogeneous heat distribution.

Precise Heat Control: Water absorbs the heat from the heater, preventing overheating. This allows bain-marie heaters to provide precise control for cooking or keeping dishes warm at low and steady temperatures.

Technical Specifications of Bain Marie Heaters

Bain-marie heaters are specialized heating elements with unique designs and features. Here are some basic technical specifications of bain-marie heaters:

Power (Wattage): The power of bain-marie heaters is typically measured in watts. This determines how much the heater can heat up and the speed of the heating process. For example, power levels such as 1000W, 1500W can be utilized.

Voltage: Most bain-marie heaters operate at standard household electric voltage, which is 220V or 230V. However, there may be instances in industrial applications where different voltages are required.

Material: Bain-marie heaters are usually made from heat-resistant materials such as stainless steel or nickel-chromium alloys. Stainless steel provides durability and resistance to corrosion.

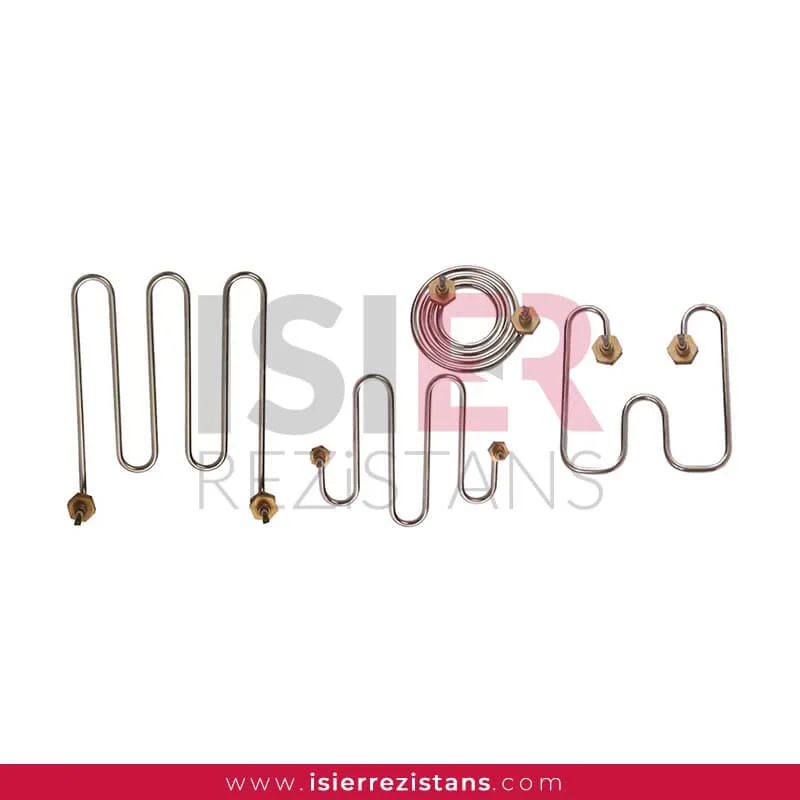

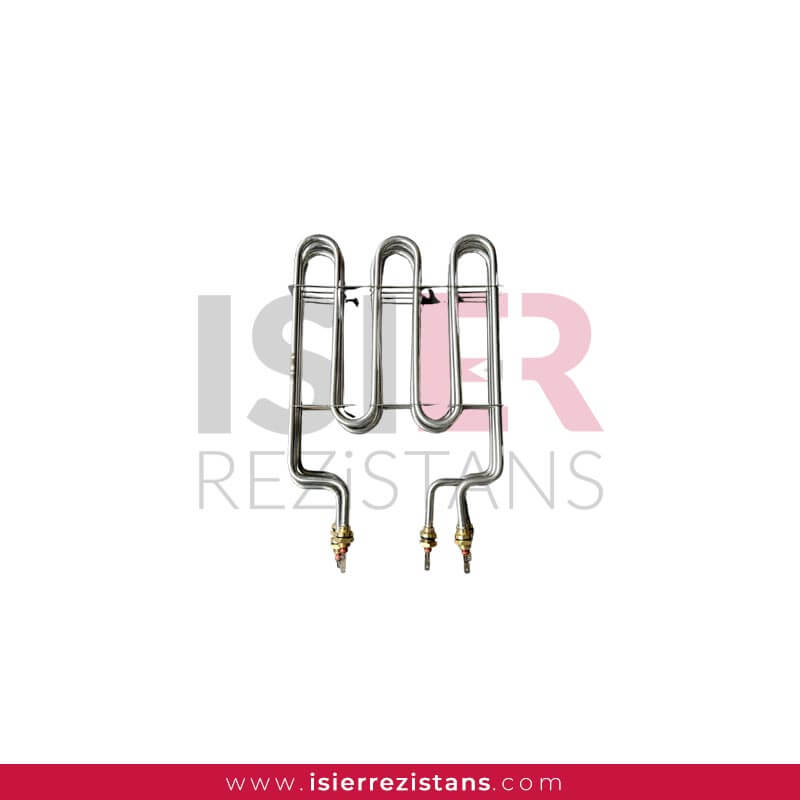

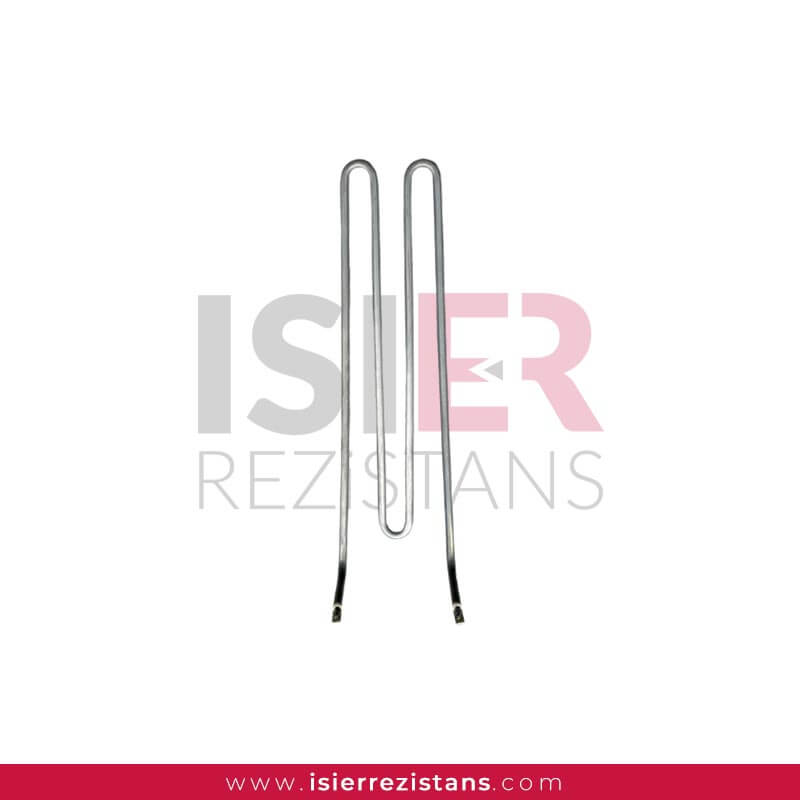

Size and Shape: Bain-marie heaters can come in different sizes and shapes. Custom designs may be used to fit specific kitchen equipment.

Water Bath Capacity: There may be a capacity value indicating the amount of water in the container where the bain-marie heater will be used. The correct amount of water is important for ensuring homogeneous heat distribution.

Heat Control: Some bain-marie heaters may be equipped with integrated temperature sensors or thermostats. This feature ensures that the water is maintained at a specific temperature.

Ease of Installation: The installation of bain-marie heaters should be designed for easy integration into kitchen equipment by users. Standard connection points and installation instructions provide convenience to users.

Durability and Waterproofing: High-quality bain-marie heaters should be resistant to water. Durability can be enhanced using stainless steel or special coatings.

Safety Features: Bain-marie heaters may have safety features to prevent overheating and ensure safe usage. Features like automatic shut-off or protection against overheating enhance user safety.

These technical specifications are important factors that determine the performance and ease of use of bain-marie heaters. It is important for users to pay attention to these features when selecting a bain-marie heater that meets their needs.

Why Should Bain Marie Heaters be Preferred?

Bain-marie heaters are specialized heating elements ideal for cooking processes that require precise temperature control in kitchens. There are many advantages to choosing these heaters. Here are some reasons why bain-marie heaters are preferred:

Precise Cooking Control: Bain-marie heaters provide precise cooking control at low and steady temperatures using a water bath. This feature enables successful use in tasks such as melting chocolate, preparing sauces, and other delicate cooking processes.

Homogeneous Heat Distribution: Bain-marie heaters distribute heat evenly through the water bath, ensuring that food cooks uniformly. This allows for delicious and consistent results.

Protection Against Overheating: The water in the bath prevents the heater from overheating. This reduces the risk of food burning or overcooking and provides a safe cooking environment.

Ability to Cook at Low Temperatures: Bain-marie heaters stand out for their ability to cook at low temperatures. This feature allows for various kitchen applications, especially in the delicate processing of ingredients like chocolate and cream.

Versatile Kitchen Applications: Bain-marie heaters can be used in various kitchen applications such as melting chocolate, cooking cream, preparing sauces, poaching eggs, and pasteurization. This versatility provides chefs and cooks with a wide range of uses.

Energy Efficiency: The water bath helps the heater use energy more efficiently, leading to energy savings and reduced electricity costs.

Safe Usage: The water bath keeps the surrounding temperature of the heater under control, ensuring a safe cooking environment. Additionally, safety measures against overheating may be included.

Suitability for Professional and Home Use: Bain-marie heaters offer a versatile and user-friendly heating solution suitable for both professional and home kitchens.

Bain-marie heaters are a reliable and effective heating option preferred for delicate cooking processes such as baking, chocolate processing, and sauce preparation.

In Which Sectors Are Bain Marie Heaters Used?

Bain-marie heaters are widely used in various industries that require precise temperature control and cooking at low temperatures. Here are some sectors and applications where bain-marie heaters are commonly utilized:

Bakery and Pastry: Bakeries and pastry shops use bain-marie heaters for delicate pastry processes such as melting chocolate, cooking cream, and preparing sugar syrup. This ensures the delicious and flawless preparation of various pastries and desserts.

Restaurants and Hospitality: From upscale restaurants to hotels, bain-marie heaters are frequently used for preparing sauces, cooking cream, melting chocolate, and cooking special dishes. In this sector, bain-marie heaters provide chefs with precise cooking control to create creative and delicious meals.

Home Meal Production and Catering: In businesses that prepare home-cooked meals and provide catering services, bain-marie heaters are preferred, especially for meeting the need for preparing large quantities of food for special events.

Chocolate and Confectionery Production: Chocolate and confectionery manufacturers use bain-marie heaters for melting chocolate. This ensures temperature control during chocolate production, enhancing product quality.

Food Processing and Manufacturing: In general food processing facilities, bain-marie heaters can be used for the precise processing and cooking of various foods. This is an effective solution, especially in the production of sauces, creams, jams, and similar products.

Dairy Product Manufacturing: In the production of dairy-based products, especially in cooking creams and milk products, bain-marie heaters can be used. This is important for maintaining the consistency and flavor of dairy products.

University and Professional Kitchens: University dining halls, schools, and other professional kitchens may prefer bain-marie heaters for extensive meal preparation processes. This enables cooking large quantities of food and ensures precise control.

Hospital Kitchens: In hospital kitchens, especially for preparing diet meals and meeting special nutritional requirements, bain-marie heaters can be used.

Home Use: At home, especially for enthusiastic cooks and chefs, bain-marie heaters can be used for preparing various meals and desserts. Home users may prefer these heaters, especially for recipes that require precise cooking.

Bain-marie heaters are preferred in many different sectors due to their wide range of applications and precise control features.

Kitchen Heaters

Kitchen heating elements are heating elements located inside or under kitchen appliances and equipment. They are usually made of stainless steel or special heat-resistant alloys. They are used in many kitchen appliances such as ovens, hobs, grills, toasters and kettles.

How Do Kitchen Heaters Work?

Kitchen heating elements are electric heating elements that work by passing electric current. The wire inside resists the electric current and as a result of this resistance, it heats up and starts to emit heat to its surroundings. This heat provides the desired temperature to the user in the area inside or under the kitchen appliance.

What are the Technical Specifications of Kitchen Heaters?

The technical specifications of kitchen heaters include a range of factors that determine their performance and assist users in making selections tailored to their needs. Here are the fundamental technical specifications of kitchen heaters:

Power (Watt): Kitchen heaters’ power is typically measured in watts. This determines how much heat the heater can generate and the amount of heat it can provide in a specific application. Different kitchen appliances require different power levels.

Voltage (Volt): Kitchen heaters usually operate at the household electricity voltage of 220V or 230V. The voltage value must be compatible with the electrical system the heater operates on.

Material: Materials such as stainless steel or special heat-resistant alloys ensure the durability and longevity of kitchen heaters. Stainless steel is preferred for its resistance to corrosion.

Size and Shape: The size and shape of kitchen heaters should be compatible with the design of the appliance they are used in. Standard dimensions typically allow integration into ovens, stoves, and other kitchen appliances.

Resistance Value (Ohm): The ohm value of the heater indicates its resistance to current at a specific voltage. A well-designed kitchen heater should conform to the ohm value required for a particular application.

Heat Distribution and Dissipation: The design of kitchen heaters should be optimized to distribute heat evenly, ensuring that food cooks uniformly.

Ease of Installation: Heater installation should enable users to integrate them into their appliances easily. Standard mounting points and connections provide convenience to the user.

Protection and Safety: Some kitchen heaters may have features like overheating protection to prevent excessive heat buildup, which is crucial for safety.

Ease of Cleaning: Heat-resistant materials and proper design facilitate easy cleaning of kitchen heaters.

Compatible Design: Kitchen heaters should be designed to fit the aesthetics of the appliance they are used in, allowing integration into various kitchen appliances.

These technical specifications enable kitchen heaters to adapt to a specific kitchen appliance or system, operate effectively, and provide users with reliable heating performance.

What are the Uses of Kitchen Heaters ?

Kitchen heating elements are heating elements used in a range of kitchen appliances. With a wide range of applications, kitchen heating elements are designed to meet a variety of cooking and heating needs. Here are some areas where kitchen heating elements are commonly used:

Ovens: Kitchen heating elements allow food to cook by heating the air or surface inside the oven. They are used in ovens with top and bottom heating features.

Stoves and Stove Top Heaters: The heating elements used in stoves and stovetop heaters accelerate the cooking of food by heating the surface on pots and pans.

Grills: In electric grills, the heating elements are usually located under the grill, allowing meat or vegetables to cook quickly.

Toasters: The heating elements in toasters quickly toast slices of bread or sandwiches to make delicious toast.

Kettles and Tea Makers: Electric kettles and tea makers, thanks to their built-in heating elements, can quickly heat water to make tea or hot drinks.

Microwave Ovens: Microwave ovens can use resistances as well as microwave energy to heat and cook food.

Hoods: Kitchen hoods use heating elements to absorb vapors and odors in the kitchen and clean the environment.

Deep Fryers and Deep Fat Fryers: The heating elements in deep fryers and deep fat fryers can be used to heat oil quickly.