Solar Energy Heaters

Solar heating elements are specially designed heating elements used to convert solar energy into electrical energy or to generate heat directly from solar energy. They generate electricity or provide heating using energy from the sun, usually through photovoltaic cells or thermal collectors.

How Do Solar Energy Heaters Work?

The technical specifications of solar heaters may vary depending on their usage, design, and application. However, generally, the technical specifications of solar heaters may include the following elements:

For Photovoltaic Solar Heaters:

Efficiency: Efficiency of photovoltaic solar heaters indicates their ability to generate electricity from sunlight. High-efficiency panels provide more energy production.

Power Rating: Power rating represents the maximum electrical power that the heater can generate within a specific period, measured in watts (W).

Operating Voltage and Current: These values specify the voltage and current at which the solar heater can operate, typically expressed in volts (V) and amperes (A).

Material and Design: The material and design of photovoltaic cells affect factors such as durability, lightweight, and better absorption of sunlight.

Operating Temperature: This parameter indicates the temperature range within which solar panels can operate efficiently.

For Thermal Solar Heaters:

Collector Area: Collector area refers to the surface area used to collect solar energy, measured in square meters (m²).

Efficiency: Efficiency of thermal solar heaters in converting heat energy is evaluated along with the collector area.

Maximum Temperature: This parameter indicates the maximum operating temperature of the heater.

Heat Transfer Fluid: The type and properties of the fluid used for heat transfer play a significant role in thermal energy transfer.

Durability and Protection Class: Classification indicating the resistance of solar heaters to external factors such as wind, water, and dust.

Common Technical Specifications:

Compliance and Certification: Information regarding compliance with specific standards and certifications.

Connection and Mounting Options:

Information about how the heater can be securely mounted and how energy connections can be made.

Weather Resistance: Values indicating the resistance of heaters to external weather conditions such as wind, snow, and rain.

These technical specifications are important for evaluating the performance, durability, and compatibility of solar heaters. Selecting the most suitable solar heater for each application depends on carefully examining these technical specifications.

In Which Sectors Is Solar Energy Heater Used?

Solar heaters are commonly used in various sectors for clean and sustainable energy usage. Here are the sectors where solar heaters are widely employed:

Residential Applications: Solar heaters can be used in homes for purposes such as producing hot water, heating systems, and pool heating.

Industrial Heating Systems: In industrial facilities, factories, and production plants, solar heaters are used for temperature control in processes, heating systems, and water heating applications.

Agriculture: Solar heaters can be utilized in greenhouses for cultivating and protecting agricultural products. They can be used to control soil temperature and maintain optimal conditions inside the greenhouse.

Food and Beverage Industry: In food processing plants, solar heaters can be used for hot water production, steam generation, and heating in production processes.

Water Heating Systems: Solar heaters are widely used in residential and industrial water heating systems.

Swimming Pools: Solar heaters can be used to heat swimming pools, increasing the temperature of the pool water and providing a comfortable swimming experience.

Power Plants: Solar heaters can be involved in converting solar energy into electrical energy in photovoltaic panels and thermal energy systems.

Maritime Sector: Solar heaters can be used in the maritime sector for heating systems and energy production using solar energy.

Farming and Livestock: Solar heaters can be used on farms to heat animal shelters, heat water, and meet general energy needs.

Transportation: Solar heaters can be used in charging electric vehicles and in solar-powered transportation systems.

Solar heaters are used in various applications across different sectors to reduce energy costs, decrease carbon footprint, and promote sustainable energy usage. This technology is utilized to provide both economic and environmental sustainable energy solutions.

Why Should Solar Heaters Be Preferred?

Solar heaters should be preferred due to a variety of advantages they offer. Here are some key reasons why solar heaters should be preferred:

Clean and Sustainable Energy: Solar heaters utilize solar energy, which is a clean and sustainable energy source, reducing dependence on fossil fuels and promoting environmentally friendly energy production.

Low Operating Costs: Solar energy is obtained for free through solar panels and thermal collectors, resulting in lower operating costs in the long run.

Energy Savings: Solar heaters reduce dependence on electricity or other energy sources, leading to energy savings.

Versatile Applications: Solar heaters can be used in both residential and industrial applications, including hot water production, heating systems, pool heating, and many others.

Low Maintenance Costs: Solar heaters typically require low maintenance due to durable materials used in solar panels and thermal collectors.

Utilization of Local Resources: Solar energy can be locally produced depending on the sunlight potential of an area, contributing to local economies by decentralizing energy production.

Low Carbon Footprint: Solar heaters offer a low carbon footprint by reducing greenhouse gas emissions during energy production.

Longevity and Durability: Solar heaters are typically made from durable materials and have a long lifespan, increasing the long-term return on investment.

Energy Independence: Solar heaters can increase energy independence by utilizing electricity or heat generated from solar energy.

Incentive and Support Programs: Various incentive and support programs exist in many countries to promote solar energy usage, enhancing the economic and environmental advantages of solar heaters.

For these reasons, solar heaters are preferred as a technology that provides energy efficiency, environmental protection, and economically sustainable energy solutions.

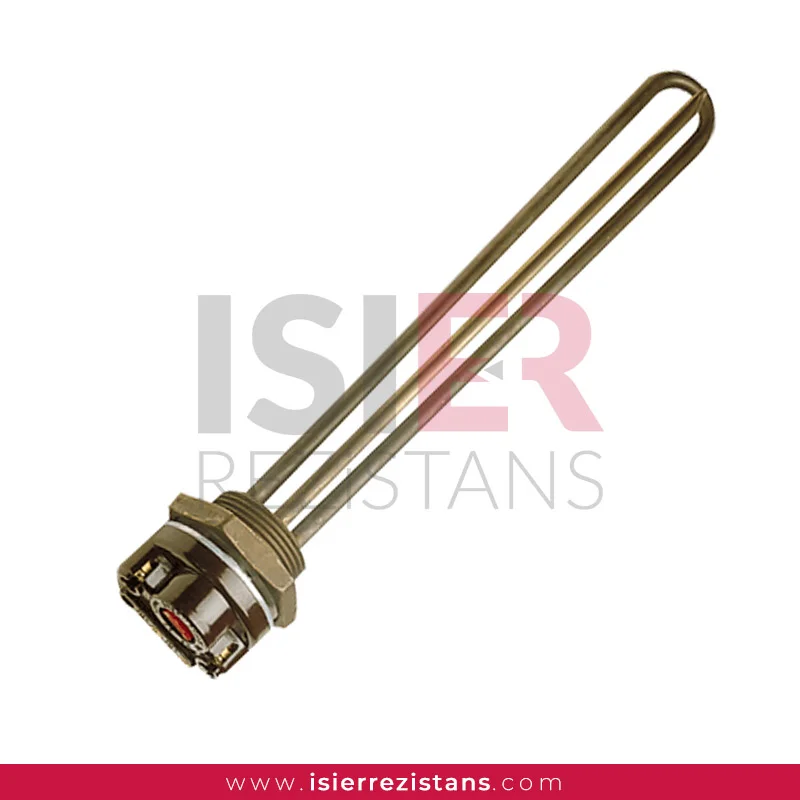

Thermovat Heaters

Termovat Heaters are a type of resistance system specifically designed to optimize heat control and precise temperature setting. These resistors react quickly to environmental temperature changes through integrated sensors and control systems, resulting in reliable and precise temperature control.

How Do Thermowat Heaters Work?

Thermovat Heaters are equipped with integrated sensors, which continuously monitor environmental temperature changes. The data collected by these sensors is transmitted to a control unit, which adjusts the operating mode of the heater to maintain the specified temperature values. Thus, Thermovat Heaters enhance energy efficiency by providing precise temperature control.

Thermovat Heaters represent one of the latest technology solutions in the product range of Heater. Designed to provide reliable temperature control in various industrial applications and home use, they offer precise temperature control, energy efficiency, and long-lasting durability. Heater once again proves its leadership in providing customers with modern and effective heating solutions through Thermovat Heaters.

What Do Thermovat Heaters Do?

Thermovat heaters are heating elements designed to provide precise temperature control, integrated with special sensors and control systems. These heaters are a technologically advanced product that allows thermal control across a wide range of applications, from various industrial uses to home usage. The primary functions of Thermovat heaters are as follows:

Precise Temperature Control: Thermovat heaters respond quickly to environmental temperature changes through integrated sensors, providing precise temperature control. This feature is used to maintain specified temperature values and keep desired temperature levels constant.

Energy Efficiency: The control unit optimizes the operating mode of the heater to increase energy efficiency. This effectively manages energy consumption and enables savings.

Longevity and Durability: Thermovat heaters are designed to be long-lasting and durable using quality materials and advanced technology manufacturing processes. This feature reduces maintenance requirements and extends the product’s lifespan.

Versatile Application Areas: Offering a wide range of applications from industrial machinery to home usage, Thermovat heaters adapt to different needs. They can be used for various heating requirements across different sectors.

Reliable Performance: Integrated sensors and control systems ensure that Thermovat heaters deliver reliable and stable performance. This feature is crucial for providing continuous and reliable heating.

Environmental Adaptability: Thermovat heaters have the ability to adapt to various environmental conditions. This is important for providing reliable performance in different industrial environments or home usage.

Easy Installation and Integration: Thermovat heaters are generally easy to use and can be easily integrated into various systems. This allows users to quickly set up and use their systems.

Thermovat heaters are a preferred heating solution in many industrial processes and home usage due to their precise temperature control and energy efficiency.

What are the Uses of Thermovat Heaters?

Thermovat heaters, with their features of providing precise temperature control and energy efficiency, can be utilized as a preferred heating solution in various industrial applications and home usage. Here are some common areas where Thermovat heaters are widely used:

Automotive Industry: In automotive manufacturing, Thermovat heaters can be used for paint drying ovens and other heating systems. This translates to precise temperature control in paint processes and other automotive production processes.

Healthcare and Medical Field: Medical devices and laboratory equipment need to operate under specific temperature conditions. Thermovat heaters can be used to provide reliable temperature control in such devices.

Home Heating and Ventilation Systems: In heating and ventilation systems used in homes, Thermovat heaters can be employed to provide energy efficiency and optimize temperature control.

Chemical Industry: In chemical production facilities, Thermovat heaters can be used for reactions and processes that require specific temperature conditions.

Room Heating and Water Heaters: In water heaters and room heating systems used in homes, Thermovat heaters can be used to provide energy efficiency and precise temperature control.

Solar Energy Systems: In solar energy collectors and systems, Thermovat heaters can increase energy efficiency by optimizing temperature control.

These usage areas demonstrate the wide range of applications that Thermovat heaters cater to and their ability to adapt to various needs in different sectors.

What are the Technical Specifications of Thermovat Heaters?

The technical specifications of Thermovat heaters include various parameters that determine their performance. Here are the general technical specifications of Thermovat heaters:

Power Capacity: The power capacity of Thermovat heaters determines how much heat they can generate within a specific period, expressed in watts (W). For example, 1000W or 5000W.

Voltage and Current Values: The operating voltage and current values of the heater are specified to ensure compatibility with the electrical system used. For instance, 220V or 380V.

Size and Shape: Thermovat heaters are manufactured in various sizes and shapes, with length typically indicated in millimeters (mm). For example, 300mm or 600mm.

Resistance Value: The resistance value of the heater is expressed in ohms and determines how much resistance the heater exhibits under a specific voltage.

Temperature Range: The operating temperature range of Thermovat heaters is specified typically in degrees Celsius (°C). For example, -50°C to 300°C.

Protection Class (IP Rating): The IP class indicating the resistance of the heater against water and dust ingress is specified. For example, IPX4.

Connection Type: The connection type of Thermovat heaters is specified, affecting their mounting and integration. This can include threaded, flanged, or other special connection types.

Control and Regulation: Some Thermovat heaters come with an integrated control unit or thermostat used to determine and control temperature values.

Heating Element Type: Depending on the design, Thermovat heaters can feature different types of heating elements such as tubular, immersion, or coil.

Material: Thermovat heaters are typically made of high-temperature-resistant alloys or specially coated materials.

Compliance and Certification: Some Thermovat heaters may comply with specific industry standards or certifications.

Safety Features: Thermovat heaters may feature safety mechanisms such as automatic shutdown in case of overheating or safety sensors.

These technical specifications illustrate that Thermovat heaters are designed to meet various application needs and can be integrated into different industrial processes.