What areTubular Heating Elements?

Tubular heaters are metal heaters commonly used in industrial sectors. They possess varying characteristics depending on resistance levels and typically function by converting electrical energy into high temperatures. These types of heaters can be produced in various forms such as liquid heaters and open heaters. With a wide range of applications from kitchen equipment to industrial machinery, tubular heaters are frequently preferred in industrial equipment due to their durable structures.

Our Products

Your Solution Partner for All Your Resistance Needs

Technical Information of Tubular Heaters

Tubular heaters are thermal components widely used in many areas such as heating metal molds and various metals in industrial furnaces, heating chemical and corrosive liquids.

Tubular heaters, with diameters ranging from 6.5 mm to 16.00 mm, can be produced in different sizes from 5 mm to 20 mm according to special needs. These heaters, commonly used in industrial, commercial, and scientific fields, consist of parts such as a metal sheath and terminal. Due to their ease of shaping, they can be welded or soldered to any metal surface, making them easily integrated into systems.

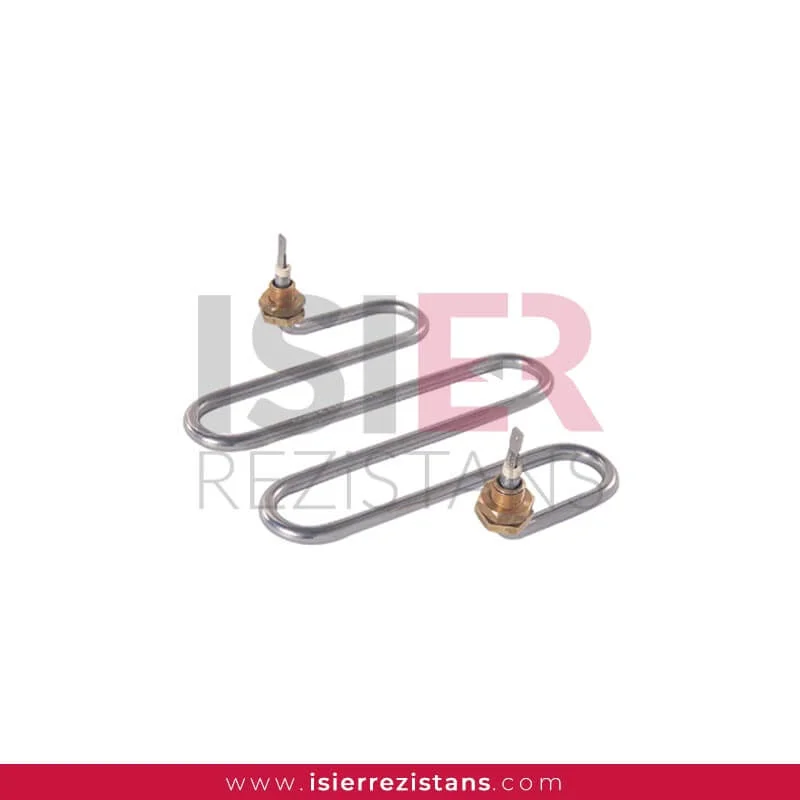

Tubular heaters can be manufactured in various types such as sleeve, finned, flanged, coiled, or aluminum-clad, and can be straight or bent as desired. For example, straight rods, U-shaped, and M-shaped are the most common forms of use.

These types of heaters are preferred for heating water, oil, chemical, and corrosive liquids in industrial environments. They are also used for heating molds and various metal materials in industrial furnaces.

Additionally, flat-shaped heaters can also be produced. These types of heaters are used in various fields such as railroad switch heating, oil heaters in industrial fryers, and dry air heaters in some special ovens.

Tubular heater models have a wide range of applications including the plastic industry, packaging industry, woodworking industry, construction industry equipment, household appliances, foundry industry, high vacuum applications, and laboratory equipment.

Tubular Heating Types

Tubular heaters can come in various sizes, shapes, materials, and features, and can be classified into various types based on these characteristics. Here are some types of tubular heaters:

1. Electromagnetic Tubular Heaters: These types of tubular heaters, made from metal materials such as nickel, tungsten, carbon, or their mixtures, convert electrical current through resistance.

2. Thermistor Tubular Heaters: These types of tubular heaters rely on the change in resistance with temperature. As the temperature increases, the resistance decreases, and vice versa.

3. Radial Tubular Heaters: Tubular heaters that can be designed in different sizes and provide resistance according to the direction of flow.

4. Axial Tubular Heaters: Tubular heaters that provide resistance when the fluid moves horizontally.

5. Thermostatic Tubular Heaters: Tubular heaters that can be used with temperature control systems and can change their resistance when a certain temperature value is reached.

This classification can vary depending on the application, operating conditions, and requirements of tubular heaters, and combinations of different types can also be used.