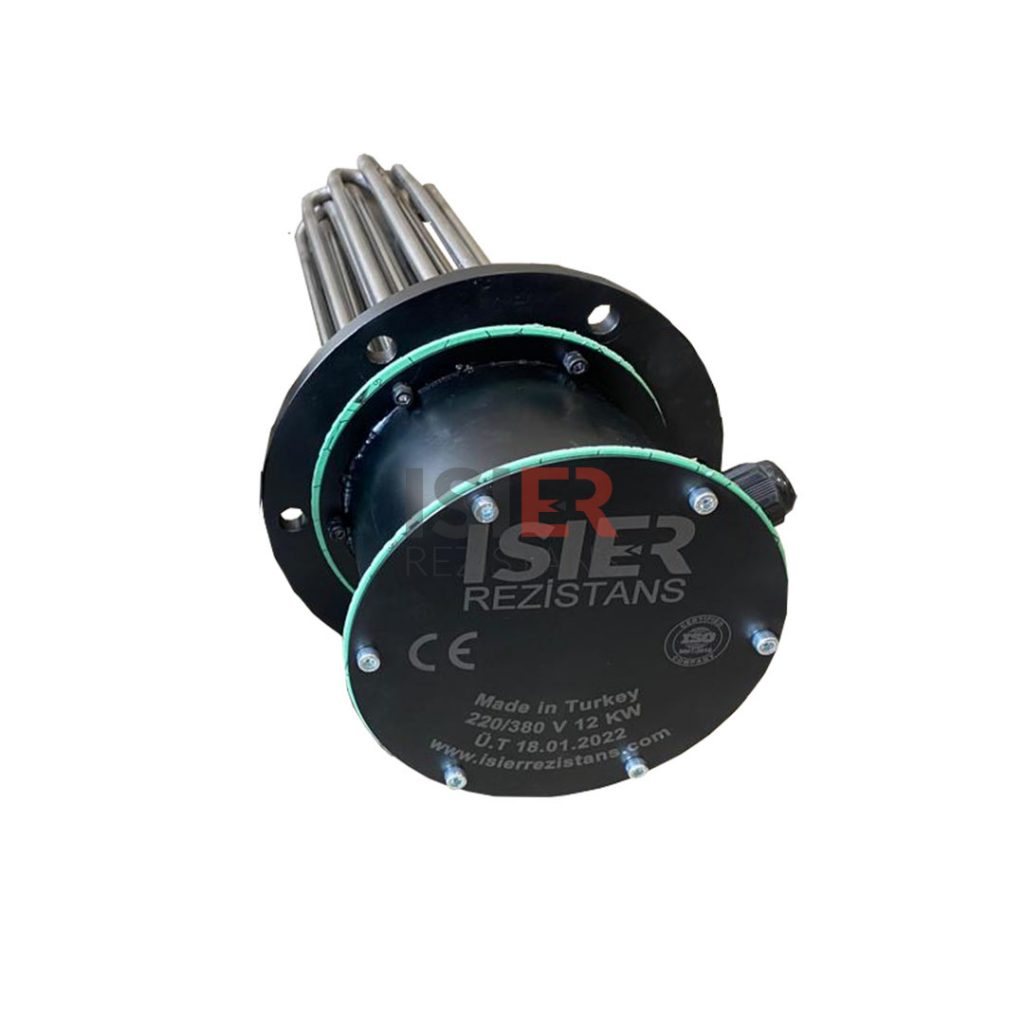

Flanged Heaters

Flanged Heaters a type of resistance specially used for tanks with or without pressure tanks. These products are used to heat liquids and gases in tanks or tanks.kW promises effective solutions in applications in need.Normal or sealed energy box is installed in front of the flange. The electrical connection is obtained with the help of amperage klemens or bars. Flanged Heaters used in industrial machinery as well as electrical appliances in furnaces that not rise above 500 degrees dry. It is also a product that can be preferred in the heating of liquid substances. These products can be produced in order-specific sizes and powers according to different needs and usage purposes.

Flanged Heaters are used in many machines and materials, especially in industrial areas. These products are produced from different substances. It is used in the production of materials such as chrome, copper, brass, iron, glass or titanium depending on the need. The materials to be used vary according to the situations such as for what purpose.

Technical Information

Flanged Heaters are used in many machines and materials, especially in industrial areas. These products are produced from different materials. Depending on the need, it is used in the production of materials such as chrome, copper, brass, iron, glass or titanium. The materials to be used vary according to the circumstances, such as for what purpose.

The adapter output can be designed in different ways for the resistors designed as flanged. It can be produced as an adapter output with cable output, socket output or screw output. Here, the choice is entirely up to the customer. It can be produced with different output ends depending on your request.

Flanged Heaters are often used in electrical household appliances. You can also use it in ovens that will not exceed 500 degrees. If you are going to heat liquid materials, you can choose CrNi pipe, steel pipe or copper pipe depending on your preference.

These resistances can also be used in environments such as water heating or oil heating. It can also be used in tanks or tanks where these liquids will be found. It can be used in storage or tank, regardless of pressurized or non-pressurized environment.

What is a Flanged Heating ?

Flanged heaters are a type of heating element equipped with projections or rim-like edges, known as flanges, at both ends. Flanged heaters are used to securely attach the resistance to a surface or a heating system. The heating element itself is typically made of materials such as metal, ceramic, or quartz, and generates heat by passing an electric current through it.

Flanged heaters are commonly used in industrial heating applications such as heating liquids or gases in tanks or pipes, as well as heating systems for buildings and homes. By allowing efficient heat transfer and reducing the risk of thermal stress on the heating element, flanged heaters provide a secure and stable connection to the heating system.

Flanged Heating Technical Specifications

The technical specifications of a flanged heater can vary depending on the type and manufacturer, but some general features include:

Wattage: The amount of power the resistance can produce, measured in watts (W).

Voltage: The voltage required to supply power to the resistance, measured in volts (V).

Resistance: The electrical resistance of the heating element, measured in ohms (Ω).

Maximum Temperature: The highest temperature the resistance can reach without damage, measured in degrees Celsius (°C) or Kelvin (K). Flanged heater temperature detectors (RTDs) typically withstand temperatures up to 600°C.

Dimensions: The size and shape of the resistance, including the length, width, and height of the heating element and flanges.

Material: The material used for the heating element and flanges, such as metal, ceramic, or quartz.

Connections: The type of electrical connections used to connect the resistance to the power source, such as screw terminals or cable ends.

Flange Size: The size and shape of the flanges, including the diameter and bolt holes.

Certifications: Certifications and safety standards met by the resistance, such as UL, CE, or CSA.

Considering these features is important when selecting a flanged heater for a specific heating application, as they can affect the efficiency, durability, and safety of the heating system.

Flange Heater Usage Areas

Due to their high power ratings, durability, and versatility, flanged heaters are used in many industrial and electrical applications. Some common areas of use include:

Power distribution systems: As load resistors for voltage regulation and power control.

Power electronics: To control power flow in AC/DC drives, inverters, and rectifiers.

Electric motors: To control the speed and torque of electric motors.

Welding equipment: To control the current in welding machines.

Test and measurement equipment: As load resistors to test electrical equipment and measure electrical parameters.

Flange Heater

Flanged heaters are specially designed heaters for heating liquids or gases in tanks and storage facilities. These products offer effective solutions for applications requiring high kW power. Flanged heaters typically have a standard or sealed electrical enclosure at their front. Electrical connection is usually provided via high-amp terminals or bars. These types of heaters are also used in industrial machinery and household electrical appliances and are often preferred in ovens operating below 500 degrees. Additionally, they are commonly used for heating liquid substances. Flanged heaters can be manufactured in special dimensions and powers according to different needs and usage purposes.

Flange Heaters Technical Details

Flanged heaters are commonly used in industrial sectors and can be manufactured from various materials. The choice of material depends on the purpose and conditions of the heater; for example, materials such as chrome, copper, brass, iron, glass, or titanium may be preferred.

Adapter outputs for flanged heaters can also be designed in different ways. These outputs can be produced as cable, socket, or screw outputs, and the preference belongs to the customer. They can be customized according to the desired output type.

Flanged heaters are frequently used in household electrical appliances and can also be used in ovens that do not exceed 500 degrees. Various options such as CrNi tubular, steel tubular, or copper tubular are available for heating liquid substances.

These types of heaters can also be used in environments such as water or oil. When preferred in tanks or storage units, they can be used in pressurized or unpressurized environments.

The technical specifications of a flanged heater can generally vary depending on the manufacturer and intended use. However, the following features are typically considered:

– Wattage (W): The amount of power the heater can generate, expressed in watts.

– Voltage (V): The amount of voltage required to power the heater, measured in volts.

– Resistance (Ω): The electrical resistance of the heating element, measured in ohms.

– Maximum Temperature: The maximum temperature the heater can withstand without damage, usually expressed in degrees Celsius or Kelvin. Flanged heater temperature detectors (RTDs) can typically withstand temperatures up to 600°C.

– Dimensions: Measurements such as the length, width, and height of the heater and flanges.

– Material: The material used for the heating element and flanges, typically metal, ceramic, or quartz.

– Connections: The type of connections used to connect the heater to the power source, such as terminals or cable ends.

– Flange Size: Dimensions of the flanges, including diameter and bolt holes.

– Certification: Safety standards and certifications met by the heater, such as UL, CE, or CSA.

These features can affect the performance, durability, and safety of the heating system. Therefore, it is important to consider these technical details when selecting a suitable flanged heater for a specific heating application.

Application Areas of Flange Heaters

Flanged heaters are utilized in various industrial and electrical applications due to their high power capacities, durability, and versatility. Some common usage areas include:

Industrial Heating: Used in applications such as industrial ovens, furnaces, drying systems, and heating tanks to heat liquids and gases.

Chemical Industry: Widely used for heating liquids and gases and controlling reactions in chemical processes.

Food Industry: Used for heating liquids and solids in food processing equipment.

Plastic Industry: Utilized for heating processes in extrusion machines, molding machines, and other plastic processing equipment.

Energy Generation: Can be used as load resistors in power distribution systems for voltage regulation and power control.

Electric Vehicles: Employed to control power flow in power electronics applications such as electric motors, inverters, and rectifiers.

Test and Measurement Equipment: Used as load resistors for testing electrical equipment and measuring electrical parameters.

Welding Equipment: Utilized for controlling current in welding machines and managing welding processes.

In these fields, flanged heaters offer high-performance and reliable heating solutions, aiding in the effective and efficient execution of many industrial processes.